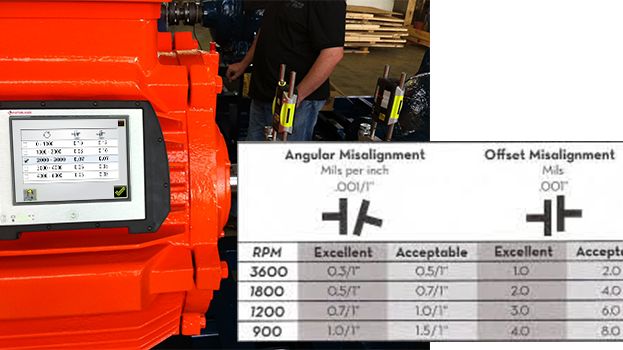

Know Your Alignment Tolerance

Fixturlaser have done what we will to form the exactness shaft alignment method faster and easier for the user of our tools. To help maintenance personnel throughout alignment a tolerance table “pops up” on the unit screen (of our tools) once getting into dimensions for the machines being aligned. The tolerances square measure supported industry standards.