Performing Shaft Alignment on a Caterpillar!

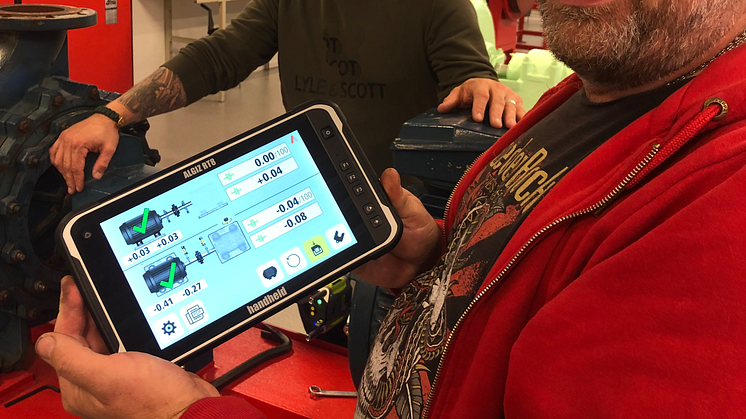

RT-300 Solution's laser alignment, vibration analysis & Run Out Probe helped align Caterpillar engine to backup floodwater pump.

RT-300 Solution's laser alignment, vibration analysis & Run Out Probe helped align Caterpillar engine to backup floodwater pump.

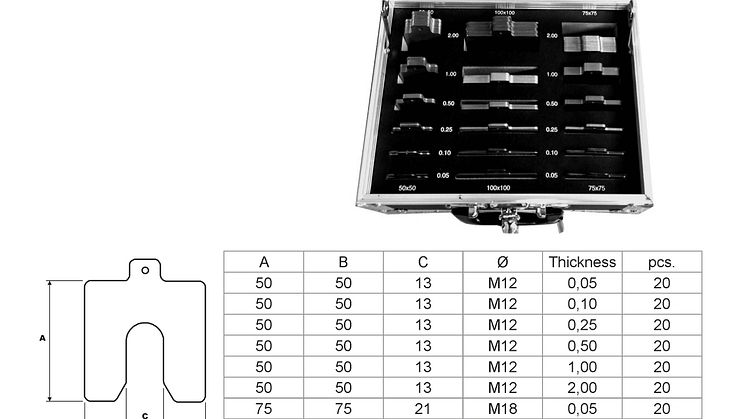

Har du någonsin lagt till antalet shims som ditt uppriktningsverktyg säger att du ska göra bara för att upptäcka att din maskin fortfarande inte är korrekt? Detta är en frustrerande men vanlig förekomst. Var det ett beräkningsfel eller gav ditt axeluppriktningsverktyg dig fel information? Mer än troligt är dina shims är skyldiga.

Tolerances for shaft alignment are typically expressed in terms of angle and offset. It is common knowledge that offsets cause confusion, but angularity often confuses those tasked with aligning or verifying alignments.

There are two parts that must be understood, proper phasing and angularity of the input and output shafts.

We are pleased to announce the launch of our new improved GuideU™ (UI), designed to maximize user productivity, facilitate intuitive reporting, and ensure a consistent user experience across all measurements.

These are the five questions every maintenance supervisor needs to answer.

The adaptive user interface will guide you throughout the measurement and alignment process. We are especially proud of the function – VertiZontal Moves™ – where you only have to measure once before making the required vertical and horizontal adjustments. Quite a time conserver in a time strained maintenance world!

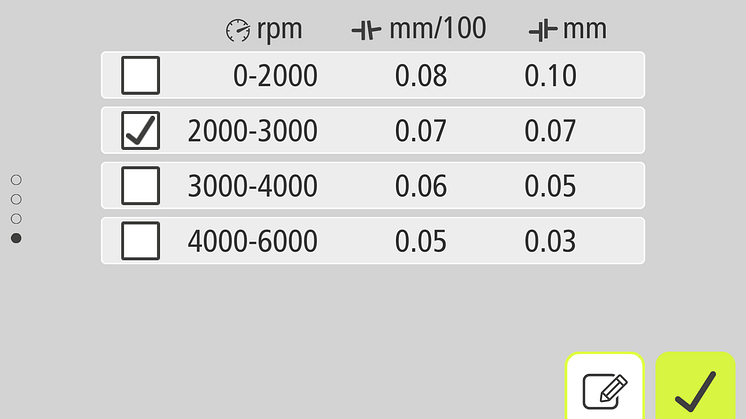

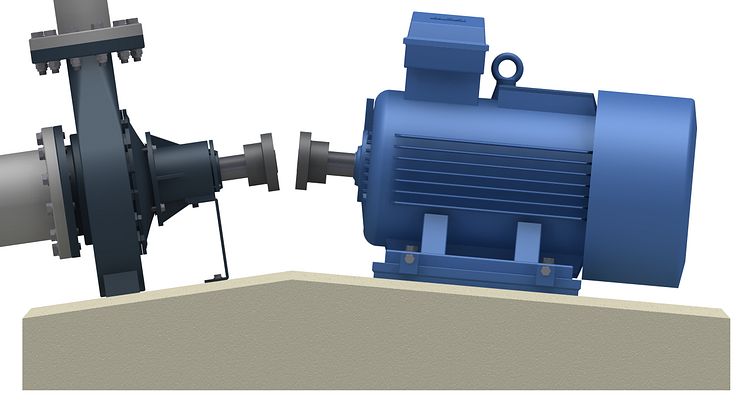

There were huge differences between coupling alignment tolerances and precision shaft alignment tolerances during a recent Acoem RT-300 training class. Electric motors and centrifugal pumps fitted with grid couplings of model 1070T were aligned at 1800 RPM. A contractor performed the initial alignment on this fairly new installation.

Verifying your machines' issues using phase analysis can be a very effective method of verifying faults discovered during an inspection. Vibration programs can be made more effective when phase, particularly cross-channel phase analysis, is applied properly.

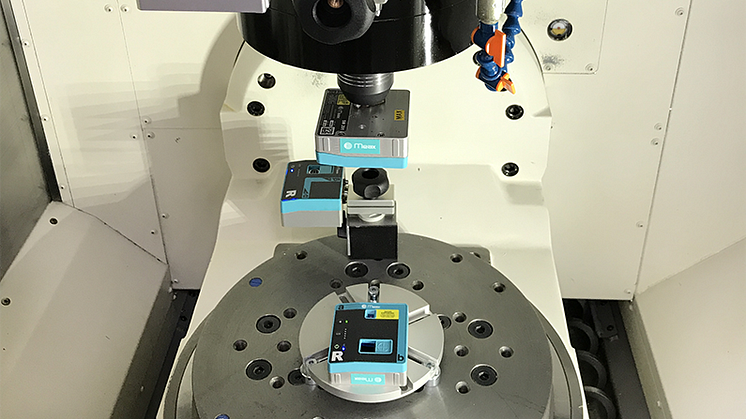

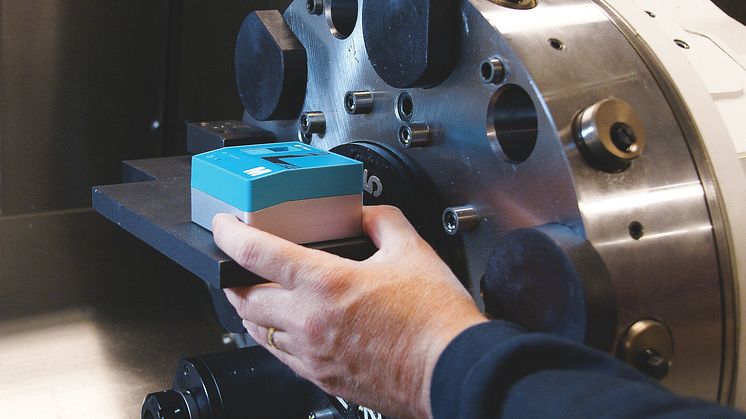

The machine tool industry has been around for a long time and it is exciting to see how the industry continues to thrive and incorporate new technology and processes. What do you think the future might hold for this industry?

The machine tool world can be overwhelming if you are new to it. You may hear terms like tolerances, CNC, CPK, surface finish, uptime, and cost per part thrown around, and it may seem like a foreign language if you are just starting out in this industry.

CNC machine leveling is an essential function. Optimizing a machine's capability and producing high-quality parts is a key element of its capability.