Pressmeddelande -

The Maintenance Supervisors 5 Questions

I’ve never been a maintenance supervisor, but I have worked for several. And when a machine has had problems, most maintenance supervisors have 5 questions:

- What’s wrong with it?

- How bad is it?

- How much longer can we run it?

- What do we have to do to fix it?

- (…and if they’re really good) What can we do to prevent it from happening again?

The challenge is that all of these questions are reactive-they happen after problems occur.

The best way to answer the 5 questions – would be to not ask them in the first place – by designing, installing, and maintaining equipment with precision and reliability.

Industrial maintenance has implemented many programs and processes such as root cause failure analysis, Six Sigma, reliability engineering, etc., to catch problems. At the same time, they are small (or even non-existent) to minimize unplanned downtime and improve equipment life. One method that sometimes gets overlooked is precision maintenance. Precision maintenance simply means installing and maintaining equipment with precision. It’s much like the weather – everybody talks about it, but not many do anything about it.

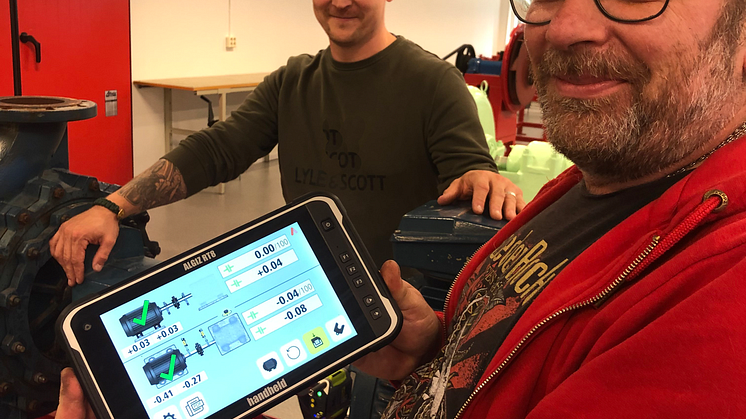

Some years ago, we implemented a course we call RPM-Reliable Precision Maintenance. Think of it as a crash course in precision maintenance. We started this course as a response to challenges we saw in our alignment training classes and problems we saw in the field.

In order to perform precision maintenance, the 21st-century maintenance mechanic or technician must know:

- what misalignment is, and the problems it causes to bearings, seals, and couplings.

- How to install belts and sheaves properly, including belt type, tension, alignment, and ventilation.

- How to read a micrometer, confirm proper shaft and bore sizes, and understand bearing nomenclature.

- Clean lubrication practices, grease delivery, and the importance of not mixing lubricants.

- How can laser alignment, vibration analysis, ultrasonics, infrared, and other reliability technologies be implemented to do it right and do it once?

- Understand the basics and nuances of power transmission equipment.

- And more…

By doing these things, you may prevent many instances of asking the 5 questions.

Let us help you to stop asking the 5 questions!

Ämnen

Kategorier

Together with 150 distributors, our 800+ employees work across 26 offices, 5 manufacturing facilities and 3 R&D centres in 11 countries

Acoem links possibilities with protection.

For more information visit acoem.com.