Performing Shaft Alignment on a Caterpillar!

RT-300 Solution's laser alignment, vibration analysis & Run Out Probe helped align Caterpillar engine to backup floodwater pump.

RT-300 Solution's laser alignment, vibration analysis & Run Out Probe helped align Caterpillar engine to backup floodwater pump.

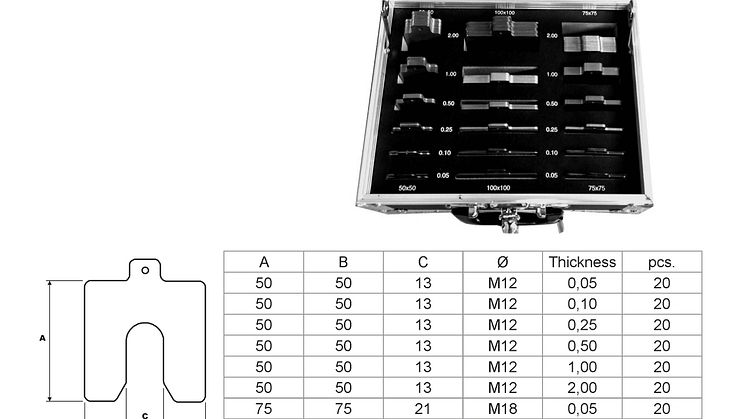

Har du någonsin lagt till antalet shims som ditt uppriktningsverktyg säger att du ska göra bara för att upptäcka att din maskin fortfarande inte är korrekt? Detta är en frustrerande men vanlig förekomst. Var det ett beräkningsfel eller gav ditt axeluppriktningsverktyg dig fel information? Mer än troligt är dina shims är skyldiga.

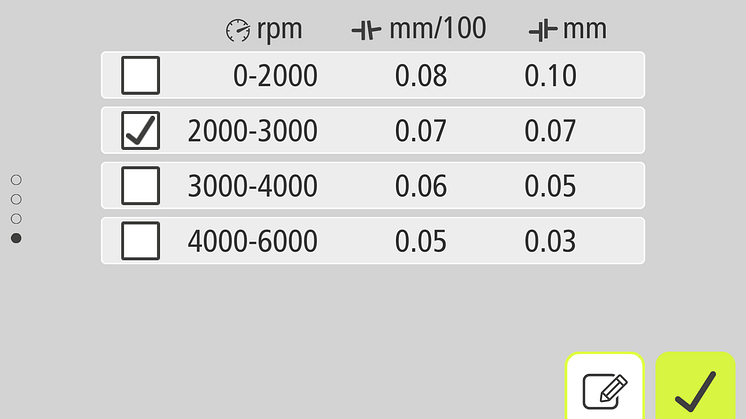

Tolerances for shaft alignment are typically expressed in terms of angle and offset. It is common knowledge that offsets cause confusion, but angularity often confuses those tasked with aligning or verifying alignments.

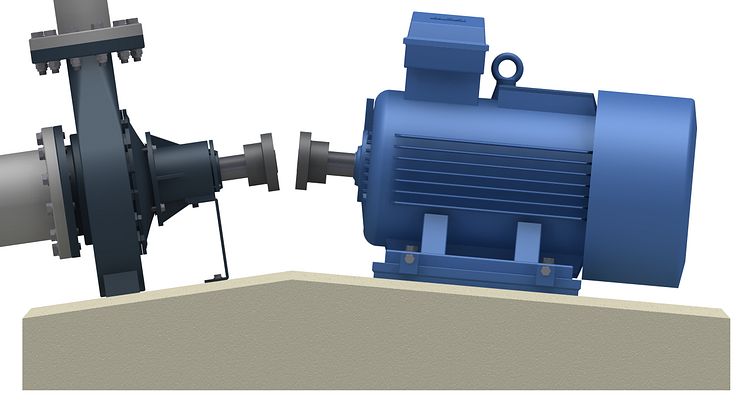

There were huge differences between coupling alignment tolerances and precision shaft alignment tolerances during a recent Acoem RT-300 training class. Electric motors and centrifugal pumps fitted with grid couplings of model 1070T were aligned at 1800 RPM. A contractor performed the initial alignment on this fairly new installation.

When using a straightedge to perform a shaft alignment you won’t see angular misalignment.

To calculate the cost of misalignment, first determine the cost of the machine’s downtime.

The NXA Runout Probe is a simple electronic tool designed to detect and measure shaft runout. The new tool represents a unique application of a linear variable displacement transducer (LVDT) to provide an easy-to-use but highly accurate measure of machinery problems that can confound the measurement and correction of shaft misalignment

As of September 15, 2014, Elos Fixturlaser AB changes its company name to ACOEM AB. Please note that this is only a name change. The company’s corporate identification number, addresses, as well as all company contact information remain unchanged.

Elos Fixturlaser has been acquired by the French company ACOEM. The acquisition strengthens ACOEM’s position in its strategy in the field of predictive maintenance. Complementing the French company’s ONEPROD condition monitoring solutions, Fixturlaser’s innovative laser based shaft alignment tools will position ACOEM as market leader in the field of smart industrial maintenance.

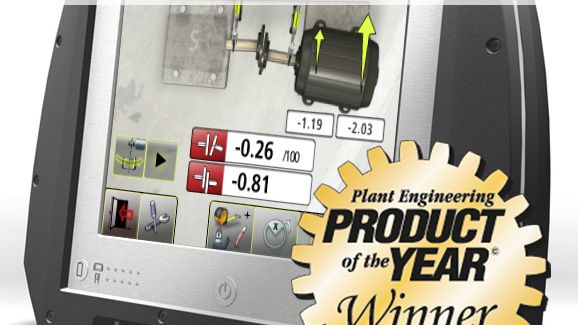

Fixturlaser has developed a new shaft alignment tool, Fixturlaser EVO, which features our unique adaptive user interface. The tool’s simplicity in its handling is characteristic for all Fixturlaser tools; an alignment tool that can be handled by all maintenance professionals, and not only experts.

Fixturlaser is proud to announce that the Fixturlaser NXA Pro has received the 2013 Bronze Product of the Year award in the Maintenance Tools & Equipment category. This laser alignment system features many innovations in shaft alignment, including the first use of gyroscopes, improved power management with extended battery life, and a 6.5 inch touch screen with video game style realistic graphics.

The Fixturlaser NXA Geometry package includes software for standard straightness, bore alignment, circular and rectangular flatness. The measurement and adjustment process is achieved promptly and easily thanks to the unique intuitive graphic user interface with live values displayed in micron resolution.