Soft Foot–What It Is and How to Minimize It

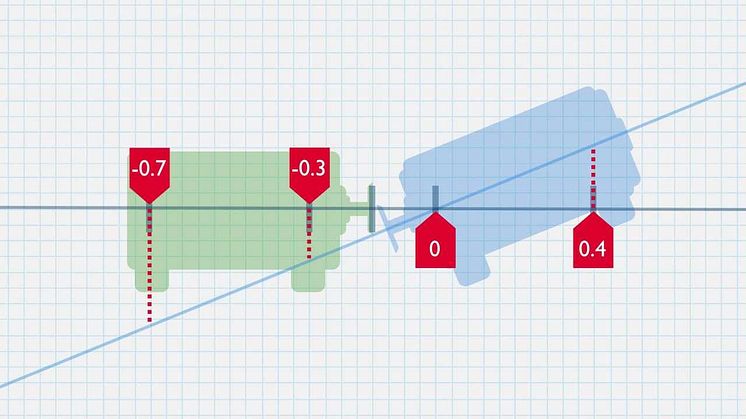

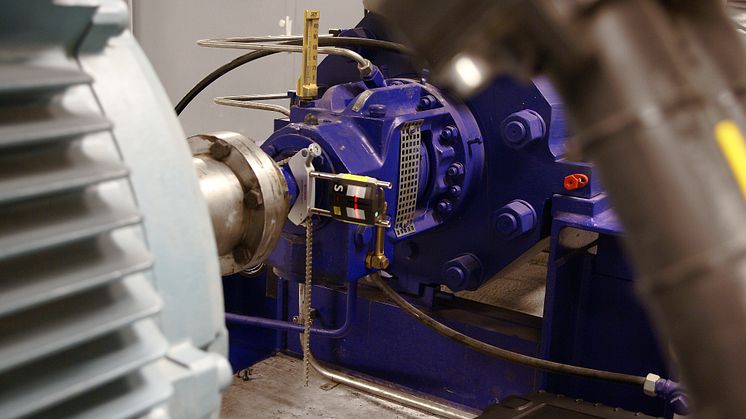

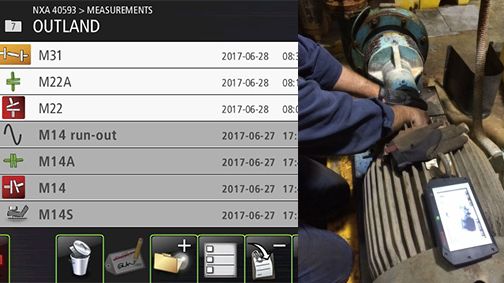

Soft foot is a common issue when aligning rotating equipment. It is a major cause of repeatability problems in shaft alignment measurements. In addition to alignment quality and repeatability problems, it can be a cause of machinery vibration, reduce life in electric motors, and cause internal clearance problems in gearboxes and pumps.