What is the Fixturlaser NXA Runout Probe?

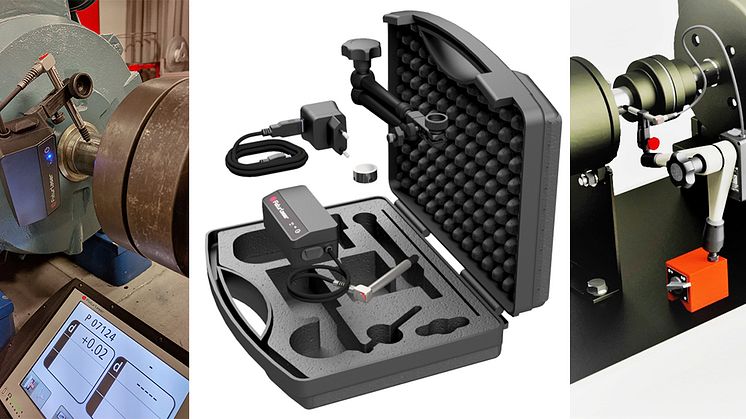

Coupled with the NXA Professional, it’s a run out probe. A dial indicator. A micrometer. A documenter. And a great diagnostic troubleshooting tool!

Coupled with the NXA Professional, it’s a run out probe. A dial indicator. A micrometer. A documenter. And a great diagnostic troubleshooting tool!

This is an obvious statement and most of us know what happens when we do “ASSUME” with most things in life. However, we (The VibrAlign Trainers) see assumptions being made quite often during a precision shaft alignment.

Several years ago, I read a book titled “A Millwright’s Guide to Motor/Pump Alignment” by Tommy “T-Hammer” Harlon (available through Industrial Press). Tommy’s book deals with a

While at facilities across the country I noticed a lack of understanding regarding the need for precision alignment of offset shaft driven rotating equipment. I myself have seen electricians and mechanics alike becoming frustrated trying to determine the cause of speed fluctuations and vibration in offset shaft driven equipment.

Have you ever struggled with a precision shaft alignment, even though you did everything right? (Preformed the pre-alignment steps, controlled backlash, etc., etc.) So, what was different? Maybe it was pipe strain.

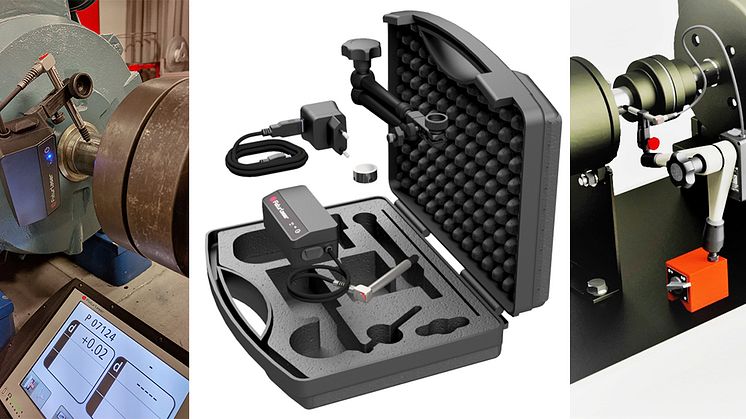

The Fixturlaser Runout Probe, an accessory for the Fixturlaser NXA Pro and Fixturlaser NXA Ultimate, is an electronic tool designed to detect and measure shaft runout and pipe strain. Runout and pipe strain are often overlooked, but when present they can confound the measurement and correction of shaft alignment.

The Fixturlaser NXA Pro has been selected as the laser shaft alignment tool to be used in the Industrial Mechanic Millwright competition at this year’s WorldSkills event, being held in Abu Dhabi on October 15-18.

The Fixturlaser NXA Pro has been selected as the laser shaft alignment tool for the Industrial Mechanic Millwright competition at this year’s WorldSkills event, being held in Abu Dhabi on October 15-18. Fixturlaser is an Official Sponsor of the event.

I read an interesting article in the June/July 17 issue of Uptime Magazine. It was titled “The Reliability Impact Within the P-F Curve” by Randy Riddell. Randy is the Reliability Manager for the SCA Barton Mill in Alabama.

I encourage you to read the full article (https://reliabilityweb.com/articles/entry/the-reliability-impact-within-the-p-f-curve). The article includes the following graphic t

If possible we want to have the sensors in a horizontal plane when the live screen is activated so the sensors are in position to monitor the horizontal correction. For rotating machines with large mass or that are difficult to position precisely, this may be time consuming and/or not possible.

A customer called me, extremely frustrated, because he could not get a good alignment. “I’ve spent two hours trying to align this stupid pump!” he said. He blamed the laser, the “cheap” pump his company had, the bad base, his bad trainer (me), and anything else that came to mind.

I did not take it personally, because I’ve been there too! I listened to his frustrations, and let him vent. And

The term ”spacer shaft” includes many things!

Some people believe that precision laser shaft alignment has evolved to the point where pre-alignment steps, such as roughing in the alignment with a straightedge, are no longer needed. Well, quite frankly, those people are wrong!

The reason for roughing in the alignment has little to do with how accurately the lasers/sensors measure. It has nothing to do with how big the laser detector is, o

In industry, many couplings utilize an elastomeric insert or element. This type of coupling has many advantages, among them: Ease of replacement Ability to absorb torsional loading No need for lubrication Tolerant of slight amounts of misalignment Inexpensive

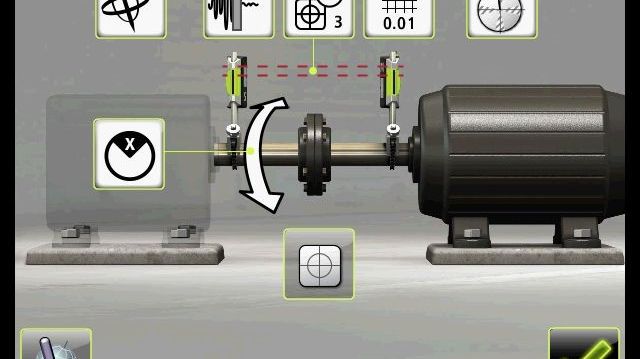

The Tripoint method of laser shaft alignment allows the user to manually take the measurements at 3 points while rotating the shafts at least 60 degrees.

I had the pleasure of working with the maintenance team at a South Carolina manufacturing plant that had an outstanding alignment kit they rolled out to every alignment job.

Welcome ACOEM India. We strengthen our team with a group with long experience of shaft alignment

Keeping equipment clean and tidy is not always the easiest thing to do when maintenance and operations has full duty schedule.

This question comes up frequently in our Shaft Alignment Best Practices training classes. The result screens below both show two different aligned machines meeting 3600 tolerances.

A recent Fixturlaser NXA Pro training class performed an alignment check of a winch driven by an 80 HP, 1800 RPM, DC electric motor with a gear style coupling. The initial results revealed a misaligned machine, with a vertical angularity over 13 times the tolerance of 0.7mils/1” (1.0 mil = .001”), vertical offset six times tolerance of 4.0 mils. The horizontal angularity was almost 4 times to