När en ”enkel” axeluppriktning inte är så enkel

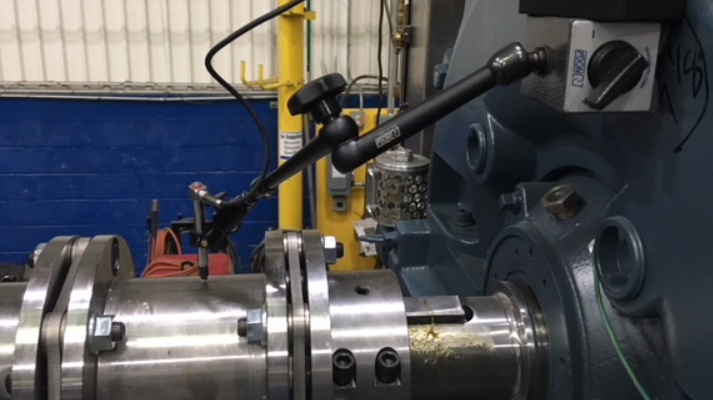

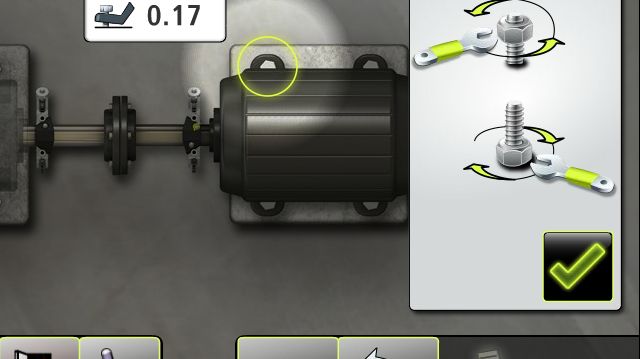

När en ”enkel” axeluppriktning visar sig vara allt annat än enkel Bakom varje lyckad uppriktning ligger noggranna förberedelser, rätt fixturer och förståelse för maskinens verkliga förutsättningar. I detta blogginlägg delar Doug Patrick med sig av varför axeluppriktning sällan är så rak på sak som den verkar – och vad du kan göra för att lyckas, även i de knepigaste fallen.