The Maintenance Supervisors 5 Questions

These are the five questions every maintenance supervisor needs to answer.

These are the five questions every maintenance supervisor needs to answer.

To calculate the cost of misalignment, first determine the cost of the machine’s downtime.

Predictive maintenance involves scheduled testing on regular intervals.

The NXA Runout Probe was introduced as an accessory to the NXA Pro and Ultimate alignment tools. As originally envisioned, the runout probe was designed with shaft and coupling runout measurements, and direct soft foot measurements in mind.

The Fixturlaser NXA Geometry package includes software for standard straightness, bore alignment, circular and rectangular flatness. The measurement and adjustment process is achieved promptly and easily thanks to the unique intuitive graphic user interface with live values displayed in micron resolution.

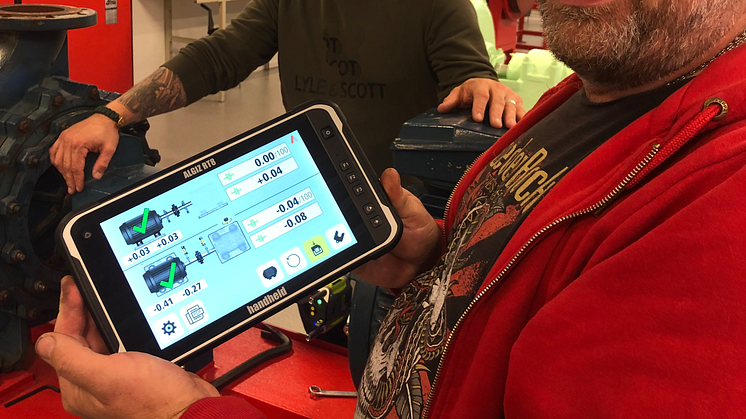

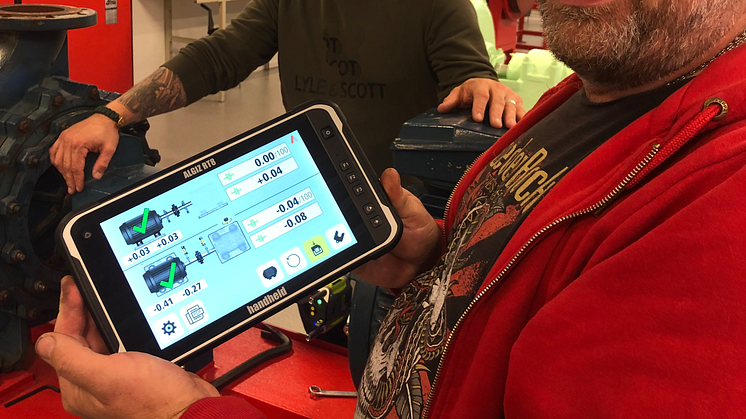

Elos Fixturlaser is launching two successors to its best-seller Fixturlaser XA; the Fixturlaser XA Pro – a complete shaft alignment tool, and the Fixturlaser XA Ultimate – shaft alignment and geometric measurements in an ultimate package solution.

The combination of modern technology and graphical user interface makes Fixturlaser XA Geometry one of this year's most innovative news in the market for geometric measurement tools.