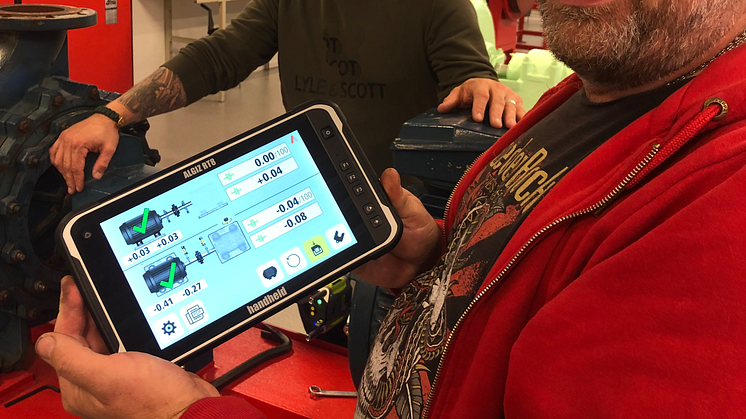

AT-200 Shaft Alignment tool - We are pleased to announce the launch of our new improved GuideU™ (UI)

We are pleased to announce the launch of our new improved GuideU™ (UI), designed to maximize user productivity, facilitate intuitive reporting, and ensure a consistent user experience across all measurements.