Utmaningar vid Axeluppriktning och hur de kan lösas.

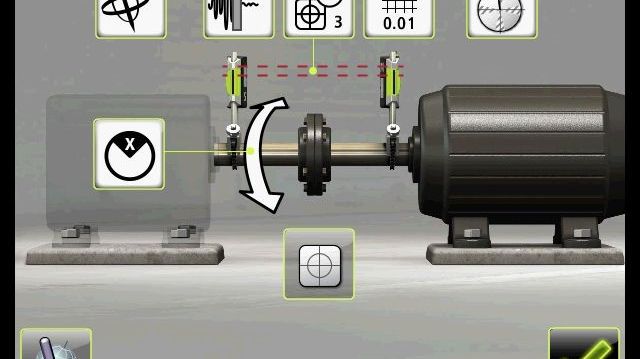

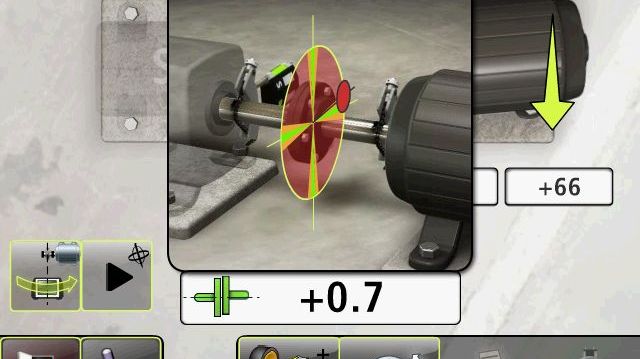

Axeluppriktning är en viktig process för att optimera maskiners prestanda och livslängd. Utmaningar som föråldrade verktyg, brist på utbildning, slitage och begränsade underhållstider kan dock skapa problem. Genom att använda moderna verktyg, erbjuda utbildning och planera underhåll noggrant kan dessa hinder övervinnas för att säkerställa effektiv drift och lägre kostnader.