Nyhet -

First delivery to Rolls Royce UltraFan™ demonstration

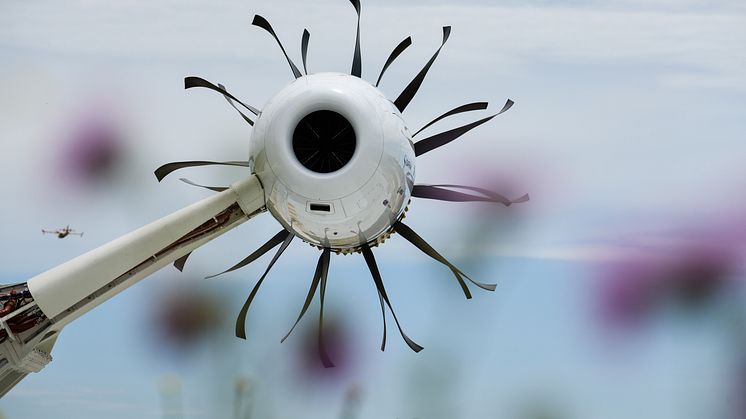

GKN Aerospace in Sweden has successfully delivered the first Intermediate Compressor Case (ICC) to the Rolls-Royce UltraFanTM engine demonstrator programme.

GKN Aerospace is a Rolls-Royce Core Partner in Clean Sky 2 with responsibility for design and manufacturing of the Intermediate Compressor Case (ICC) for the UltraFanTM demonstrator.

UltraFanTM is Rolls-Royce's next generation engine family and aims to offer a 25 % fuel efficiency improvement over the first generation of Trent engines. It features a new engine core architecture and introduces a geared design. The target is full engine ground test during 2022 and flight testing after that.

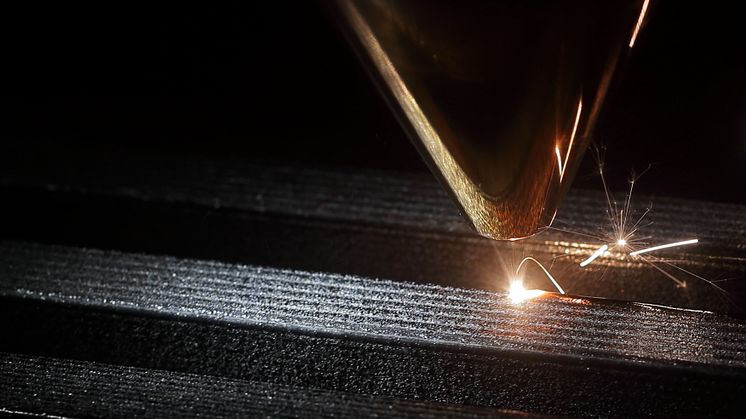

Development, manufacturing and testing of the ICC will demonstrate and validate a range of technologies, including a low cost and robust sectorised fabrication concept with castings, an innovative welding method including computer weld simulations, optimised bleed system aerodynamics and acoustics, shorter aggressive duct design, 3D printing of attaching parts and model-based design methods. In addition, GKN Aerospace has worked with a European casting house, (Howmet Tital, Bestwig, Germany) which has extended our supplier base for titanium precision castings at the same time as the foundry has gained experience in large and complex castings for aeroengines.

Clean Sky 2 is the largest European aeronautics research programme, developing innovative, cutting-edge technology aimed at reducing CO2 emissions and noise levels produced by aircraft. Funded by the EU’s Horizon 2020 programme and Europes aviation industry, Clean Sky 2 contributes to strengthening European aero-industry collaboration, global leadership and competitiveness.

The development of manufacturing processes for the ICC is also supported by the Swedish Vinnova funded IntDemo-project with special focus on developing small and medium size companies into qualified aerospace suppliers (some examples are Tooltec (machining) and AIM (additive manufacturing). Support from the Västra Götaland Region to build up a regional manufacturing technology centre is also acknowledged.