Pressmeddelande -

GKN Aerospace delivers innovative energy efficient Turbine Exhaust Module to MTU

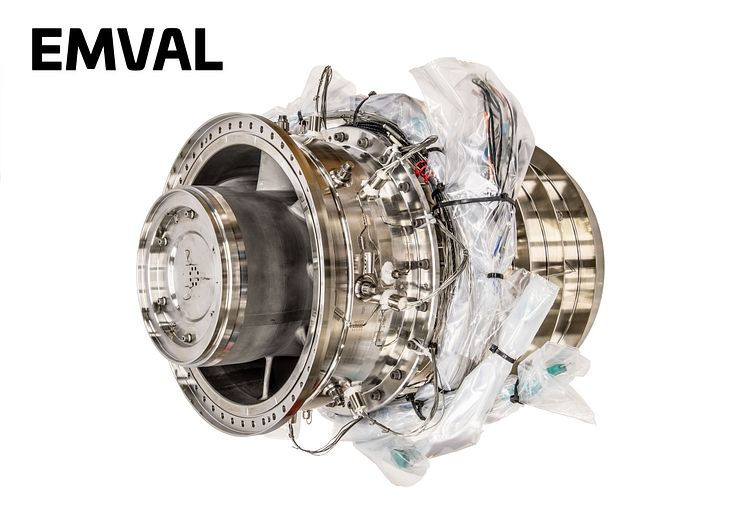

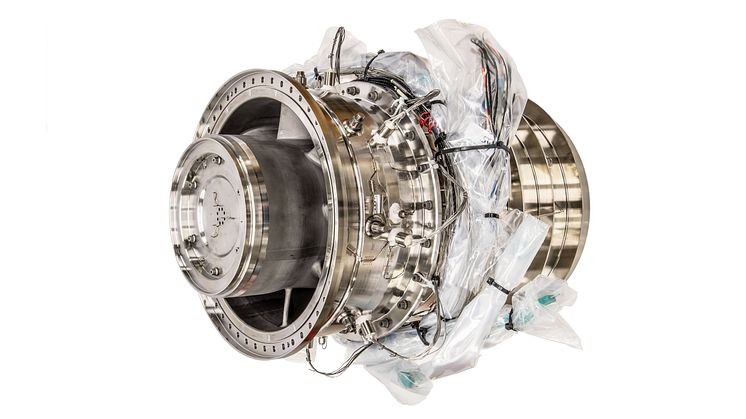

- Innovative lightweight design and manufacturing of Turbine Exhaust Module under the EU Clean Sky-2 EMVAL programme will contribute to lower carbon emissions from aviation

- The module is 20% lighter and can withstand 150°C higher temperatures compared to existing technology, contributing to increased engine efficiency and lower fuel burn

- The EU Clean Sky-2 EMVAL programme aims to validate new materials and designs for introduction in the next generation geared turbofan engines

- The development confirms GKN Aerospace’s position at forefront of the next generation of sustainable propulsion technology

GKN Aerospace engineers in Trollhättan Sweden, have successfully designed, developed and delivered a new Turbine Exhaust Module to MTU in Germany as part of the EU funded Clean Sky-2 EMVAL demonstrator programme. The Turbine Exhaust Module is paramount for heat dissipation and performance of an aero-engine and therefore a key component in improving the efficiency.

The EMVAL (Engine Material VALidation) engine demonstrator project includes the development and testing of a new MTU turbine module and a new GKN Aerospace turbine exhaust module, using an existing turbo shaft engine modified as test vehicle. The ground testing of the full-scale Engine demonstrator later this year at MTU is a key milestone in validation of the concept.

The module from GKN Aerospace includes a novel lightweight turbine exhaust case (TEC) design with separated thermal and mechanical functionality. It has been produced with extensive use of additive manufacturing (AM). The TEC consists of an inner load carrying structure and aerodynamically shaped vanes (or heat shielding fairings). This concept can withstand higher temperatures than current TEC’s, but it also saves weight as the axial length can be reduced. GKN Aerospace will be presenting a paper on EMVAL and other demonstrator programmes on 8 September at the ICAS conference in Stockholm.

Lars Ellbrant,Technology Programme Manager for the exhaust module development at GKN Aerospace said: “This type of demonstrator project is absolutely vital for GKN Aerospace in order to validate our new technologies at high TRL levels (TRL 5-6) using a full engine test together with international partners”

The aviation industry has agreed to become climate neutral by 2050 and reducing fuel consumption is fundamental to reach this goal. The engines demonstrations made within the European Clean Sky 2 programme will validate new solutions for the next generation of ultra-efficient aircraft engines. GKN Aerospace is a core partner in the Clean Sky-2 programmes

Ämnen

Regioner

GKN Aerospace Sweden i Trollhättan är en del av GKN Aerospace, en ledande global leverantör av teknologier till världens flygindustrier. Företaget utvecklar och bygger avancerade komponenter till de stora flygplanstillverkarna, både till flygplanen och flygmotorerna.

I Trollhättan arbetar ca 1700 personer.