Every watt counts: How Schaeffler is increasing the range of electric vehicles

Technical innovations by Schaeffler can increase the range of electric vehicles or enable comfort features to be used without sacrificing range.

Technical innovations by Schaeffler can increase the range of electric vehicles or enable comfort features to be used without sacrificing range.

The new mechatronic rear-wheel steering system by Schaeffler has celebrated its series-production premiere, bringing enhanced agility on bends and superior inner-city maneuverability to the new electric SUV of a renowned vehicle manufacturer. By adding steering functionality to the rear axle, Schaeffler’s new technology improves handling in city traffic and makes the vehicle easier to park.

Schaeffler is demonstrating its development capabilities in the field of hydrogen-powered mobility with a new generation of metallic bipolar plates for PEM fuel cells. All fuel cell systems rely on bipolar plates. But the plates developed by Schaeffler feature a new design optimized for large-series production and leverage an innovative coating process for long fuel cell life.

Schaeffler AG published its interim financial report for the first half of 2023 today. The Schaeffler Group’s revenue for the first six months amounted to 8,208 million euros (prior year: 7,548 million euros). The 10.1 percent constant-currency increase in revenue in the first half of 2023 was primarily attributable to growing volumes at the Automotive divisions.

Against the backdrop of ambitious climate goals and an ever-increasing awareness of sustainability issues in society, renewable energy generation is of growing importance. As market leader and strategic development partner, the global automotive and industrial supplier Schaeffler has been supplying reliable bearing solutions for onshore and offshore wind turbines for around 40 years.

Glidlager är en oumbärlig del av Schaefflers omfattande sortiment, och det finns många applikationer som inte skulle kunna fungera stabilt och tillförlitligt utan dem. Vi arbetar nära våra kunder från konstruktionsprocessens tidigaste skeden och framåt för att skapa mervärde i varje lagerposition.

Upp till 80 procent av alla tidiga lagerhaverier orsakas av felaktig smörjning. Det är här Grease-appen från fordons- och industrileverantören Schaeffler kommer in i bilden. Den kan avgöra den ideala smörjmedelstypen, smörjmedelsmängden, fettets livslängd och eftersmörjningsintervaller.

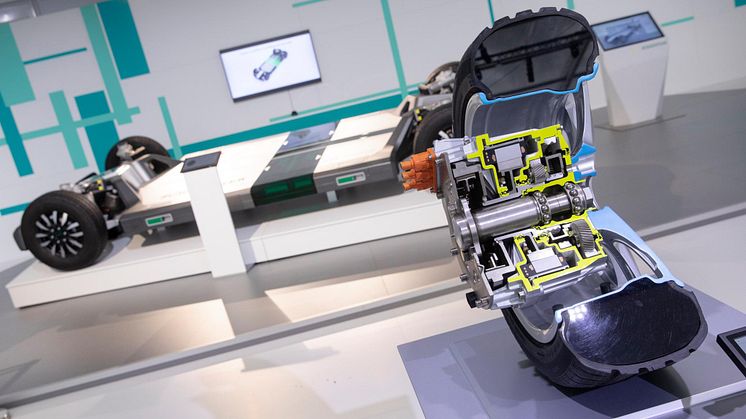

With electrification, good things come in threes, it seems. No less than three manufacturers of compact municipal vehicles are gearing up to incorporate high-efficiency electric wheel hub motors made by Schaeffler into their production lines. Fully electrified, their road sweepers, vans, and snowplow vehicles will operate with zero local CO2 emissions, leading to improved air quality.

De flesta känner till Schaeffler som en tillverkare av lager och andra komponenter och system för fordons- och industrisektorn, men inte många vet att företaget också är verksamt inom vätgasteknik. Schaeffler-tekniken används för att producera väte via elektrolys, men även för att omvandla väte till elektrisk energi.

Sustainability is an integral part of the company strategy and one of the four corporate values of the Schaeffler Group. The company accepts environmental and social responsibility along the entire value chain. In 2022, the Schaeffler sustainability strategy was aligned even more clearly with the three dimensions of Environment, Social, and Governance.

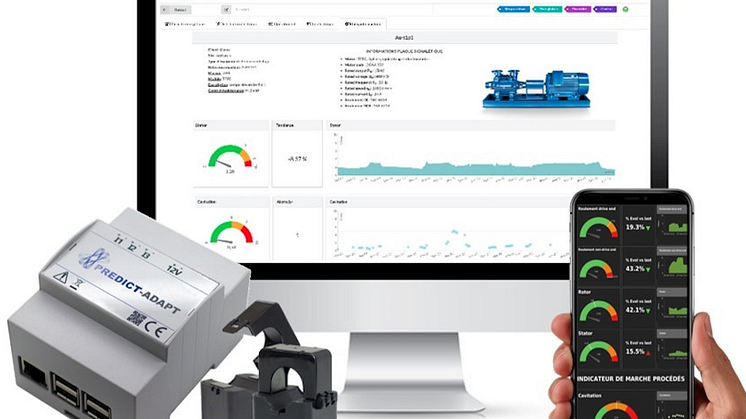

The global automotive and industrial supplier Schaeffler has announced the acquisition of 100 percent of the shares in ECO-Adapt SAS. ECO-Adapt SAS offers innovative solutions for condition monitoring based on electrical signal analysis and systems for the optimization of energy consumption.

Electric cargo and utility bikes are becoming an increasingly common sight in big cities, where they are the ideal solution for speedy, climate-friendly transportation and distribution of food, mail, medicine and more. To help with this trend, Schaeffler has been partnering with two-wheeler electric drive specialist Heinzmann GmbH & Co. KG to develop an innovative chainless drive system.

De flesta känner till Schaeffler som en tillverkare av lager, system och andra komponenter för fordons- och industrisektorn. Men för att ge kunderna det bästa stödet och för att deras produkter ska fungera så smidigt och så länge som möjligt, tillhandahåller Schaeffler även tekniska beräkningar och specifik vägledning vid särskilt viktiga installationer.

The Science Based Targets initiative (SBTi) has validated the Schaeffler Group’s targets for reducing greenhouse gas emissions as being in conformity with SBTi criteria and recommendations and hence in line with what the latest climate science considers necessary in order to meet the goals of the Paris Agreement.

The Schaeffler Group has been recognized by the global not-for-profit environmental organization CDP for its leadership in disclosure and performance relating to climate change and water security. Schaeffler has improved its score from “A-” to “A” regarding both climate change and water security, an achievement that puts it among just a handful of the companies.

How is it to work at Schaeffler? What do you do, how do you develop and what are the benefits? Schaeffler Nordics HR manager, Sara Sjödell, had a talk with Teemu Kiijärvi, Product manager for Optime Digital Service at Industrial IoT Solution Center in Jyväskylä and Rauli Kallinen, Quality assurance Lead also at Industrial IoT Solution Center in Jyväskylä, to get some insights and a better understa

Schaeffler är kanske mest känt för sina lager, komponenter och system monterade i olika maskiner eller i fordon. Men Schaefflers lager finns även i olika sportutrustningar och produkter. Ett exempel är rullskidor. I Schaeffler Nordic finns två skidentusiaster som ofta åker skidor; rullskidor på sommaren och vanliga längdskidor på vintern.

Schaefflers fokus på drivsystem för kommersiella fordon inkluderar vätgasteknik, särskilt för långdistanstillämpningar. Företaget utvecklar innovativa komponenter för bränslecellssystem och lägger grunden för att de ska kunna tillverkas i industriell skala.

Our Lifetime Solutions team recently invited key customers to a Customer Day in Jyväskylä. There were participants from 6 countries and 13 organizations attending and main objective was to get to learn more about Schaeffler and its products, services and solutions as well as listen to speakers from different industrial companies and areas sharing the best maintenance practices.

Schaefflers IoT Solution center i Jyväskylä, Finland, har under de senaste tre åren vuxit från tre anställda till cirka 25. Det finns flera förklaringar till denna tillväxt. Vi ville veta mer om denna framgång och träffade Jarno Suomela, Vice President för Solutions Business Development och en av de först anställda på kontoret i Jyväskylä.