Bild -

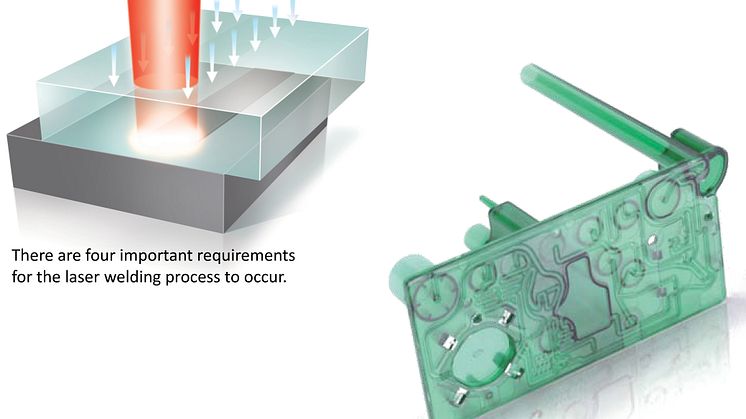

New generation of transmission tester from LPKF

- Licens:

- Creative Commons erkännande

Med en Creative Commons-licens, behåller du din upphovsrätt men tillåter andra människor att kopiera och distribuera ditt verk under förutsättning att de erkänner dig som upphovsman. Du tillåter andra att kopiera, distribuera, visa och framföra verket, samt att skapa bearbetningar av det.

- Filformat:

- .jpg

- Storlek:

- 690 x 333, 39,9 KB