Pressmeddelande -

Read More about Transmission Laser Welding of Plastics Design Guidelines “light”

Design Considerations

The follow requirements need to be addressed in your part design for a successful laser plastic weld.

Melt-Collapse

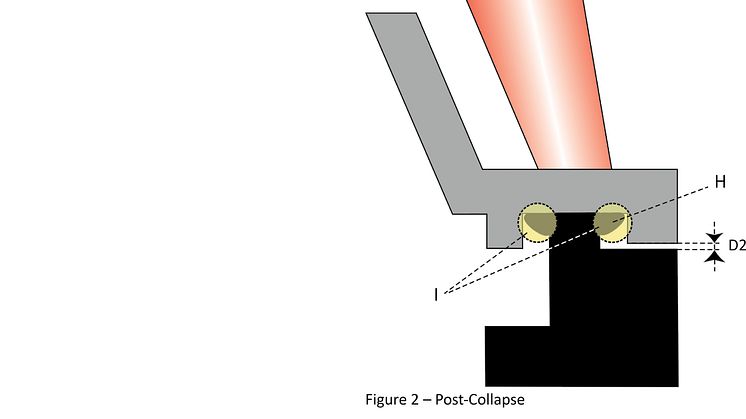

Melt-collapse (D1 and D2, Figure 1) is the distance the joining partners travel as they move together under clamping pressure. This collapse allows for material fusion and a bond to occur. If joining two flat pieces, a weld rib (E, Figure 1) will be required to allow for melt-collapse to take place.

Figure 1, above, represents a joint prior to collapse, where figure 2 shows the same joint after melt-collapse has taken place. Notice the weld flash (H, Figure 2) from the compressed rib.

Beam Accessibility

Parts need to be designed to allow direct access for the laser beam to the weld joint, shown as “A” in figure 1. Accessibility should take into consideration joint width plus part and positional tolerances.

|

Clamping technology

There must be an adequately large clamping surface on the cover to ensure the optimal application of pressure on the zones adjacent to the weld seam. The workpiece carrier must also be designed to provide good support for the housing in the zone around the root face.

Very good and reproducible positioning of the component in the workpiece carrier is crucial for uniform clamping, and the correct tracking of the joint line by the laser. This ensures that the quality of the welding results is always consistent.

Consultation and Contact Information

This information is intended as a brief introduction to laser plastic welding. Please understand these are only guidelines and your application may vary from them.

Please, contact us for design/feasibility

advice or for sample runs.

Gerhard Tetzlaff, Tel +46-(0)40-536614, E-mail: gerhard.tetzlaff@solectro.se

SOLECTRO AB

Tenngatan 6-8

SE-234 35 LOMMA

---------------------------------------------------------------------------------------------------------------------------------------

Ämnen

Kategorier

Regioner

Solectro AB grundades 1983 av Gerhard Tetzlaff.

Verksamheten omfattas av utveckling, produktion, försäljning och service av komponenter för automatisering, komplettlösningar, specialmaskiner, robotar, CNC-maskiner,PCB-prototying, laser, SMD samt dentalmaskiner.

Solectro AB är beläget i Lomma - ca. 10 minuter från Malmö och Lund.

Adress:

Tenngatan 6 - 8, 234 35 LOMMA

Tel. 040-536600

Fax 040-536610

E-mail: solectro@solectro.se

www.solectro.se