Nyhet -

Don´t miss to visit LPKF LaserWelding GmbH at the K Fair 19 - 26 October

Meet LPKF LaserWelding GmbH at the K Fair 2016

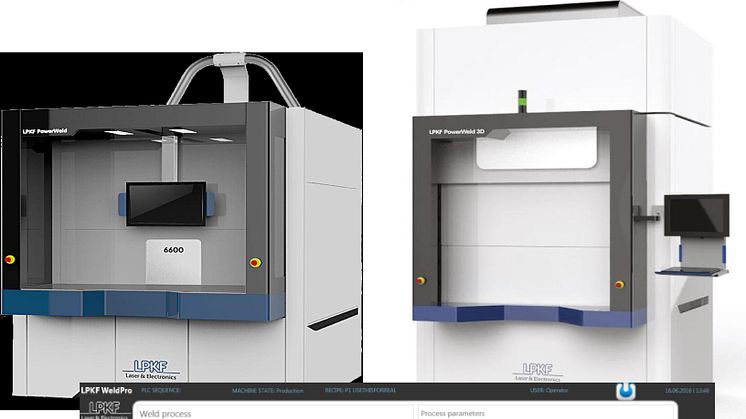

LPKF PowerWeld 6600 - Top Player

Has a new look and feel, it is designed for easy operating and

maintenance. There is a servo clamping included - homogeneous

pressure distribution without air pressure. The Soft PLC is ready

for future upgrades. The new system software LPKF ProSeT 3D with

easy process setup and faster processing routines

Increasing Value through Innovative Software

The LPKF ProSeT 3D - CAM software with contour generated from

CAD data by a click of a mouse and recognizes tool path automatically.

It gererates optimized welding path and considers crossbars of DCD

clamping devices. It uses real dimensions e.g. millimeter - offline

editing possible.

The LPKF WeldPro - system management has a system control with

modern user interface based on soft SPS. You can reteach contour

manually and process monitoring. There is a melt travel control for ok/nok

detection and scan field calibration. The LPKF WeldPro is flexible and

sustainable because of soft SPS.

Latest news at K Fair

The LPKF PowerWeld 3D 8000 is the latest news at the K -Fair

and this machine can weld large parts up to 1000 x 700 x 400 m3.

You can change the welding contour with a click of a mouse and

get a monitored welding process. This is a maintenance friendly

welding system with maximum uptime.

Don´t miss to visit LPKF LaserWelding GmbH at the K Fair

19 - 26 October in hall 11, stand 11E04.

SOLECTRO AB

www.solectro.se