Nyhet -

Laser Plastics Welding at Fakuma 2017 - Visit LPKF Laser & Electronics AG

Don´t miss to visit LPKF Laser & Electronics AG at the Fakuma, October 17 - 21.

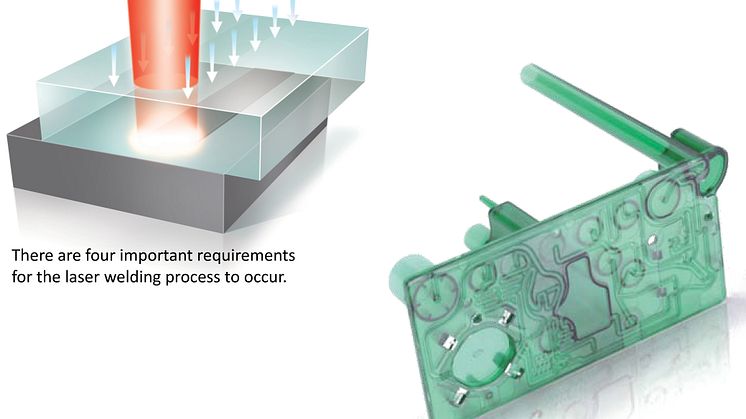

In the stand, you will learn about the exciting new options the laser welding systems offer

for the applications and machining in your production.

A few examples:

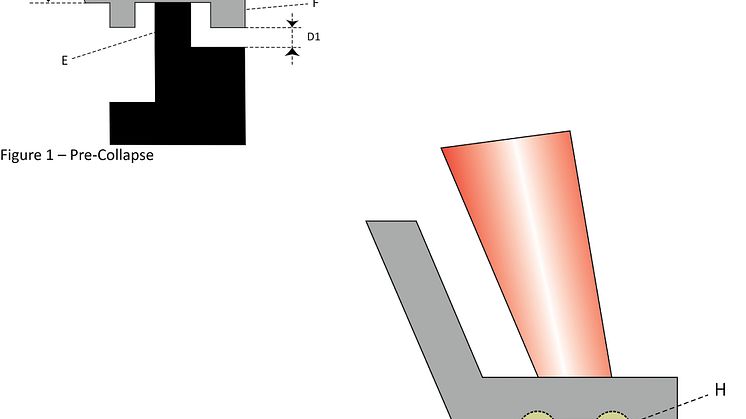

- High-speed laser welding of large 3D components with our LPKF PowerWeld3D 8000: state-of-the-art technology with variable weld seam width and joining path monitoring

- Cost-effective plastic welding direct in large series production lines: LPKF InlineWeld 6200 - the integration system also for your production line

- CAD data directly converted into optimal welding contours in just a few minutes: using the LPKF ProSet 3D software

- Quality assurance: reliable measurement of the laser transparency of materials with LPKF TMG3

Fakuma in Friedrichshafen, October 17 - 21

Booth No. 4219 in Hall A4.

LPKF Laser & Electronics AG will be happy to arrange an appointment in advance with the application experts. Simply send an e-mail to Karoline Ljung and she will help you to arrange an appointment or a free ticket for your visit.

SOLECTRO AB

www.solectro.se

Distributor for LPKF Laser & Electronics AG