Pressmeddelande -

Broad LPKF Laser Welding product portfolio at Fakuma, 14 to 18 October in Friedrichshafen, Germany

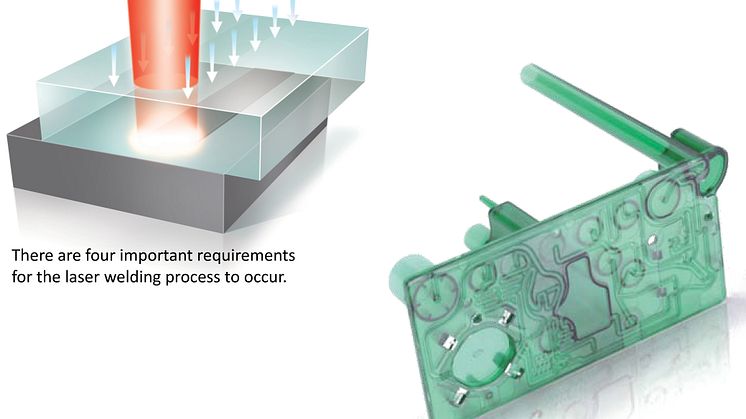

Lasers are synonymous with commercial and technological advantages. LPKF develops systems and technologies which merge new product options, flexibility and quality.

LPKF will showcase the following products at Fakuma fair from 14 to 18 October in Friedrichshafen, Germany:

- Innovative: The new LPKF PrecisionWeld welds microfluidic components and clear-clear joints without additives to create a great deal of potential for new product ideas.

- Space-saving: the compact welding systems in the LPKF InlineWeld series can be flexibly integrated because the laser source and the control unit can be installed separately from the welding head.

- High quality welds in visible parts of components: the robot-supported LPKF TwinWeld3D hybrid welding system is designed for welding large, three-dimensional free-form components in a thermal field, and is therefore ideal for welding automobile taillights.

- Multitalented: the cost-efficient laser welding systems in the LPKF PowerWeld series are perfect for the production of small and medium-sized batches, as well as for mass production. A rotary table can reduce auxiliary process time, and enable higher throughput rates.

(Hall A4, Stand 4219). Please arrange an appointment and reserve your admission ticket

by contacting gerhard.tetzlaff@solectro.se or tel. +46-(0)40-536614.

SOLECTRO AB

www.solectro.se

------------------------------------------------------------------------------------------------------------------------------------

Ämnen

Kategorier

Regioner

Solectro AB grundades 1983 av Gerhard Tetzlaff.

Verksamheten omfattas av utveckling, produktion, försäljning och service av komponenter för automatisering, komplettlösningar, specialmaskiner, robotar, CNC-maskiner,PCB-prototying, laser, SMD samt dentalmaskiner.

Solectro AB är beläget i Lomma - ca. 10 minuter från Malmö och Lund.

Adress:

Tenngatan 6 - 8, 234 35 LOMMA

Tel. 040-536600

Fax 040-536610

E-mail: solectro@solectro.se

www.solectro.se