Transmission Laser Welding of Plastics Design Guidelines “light”

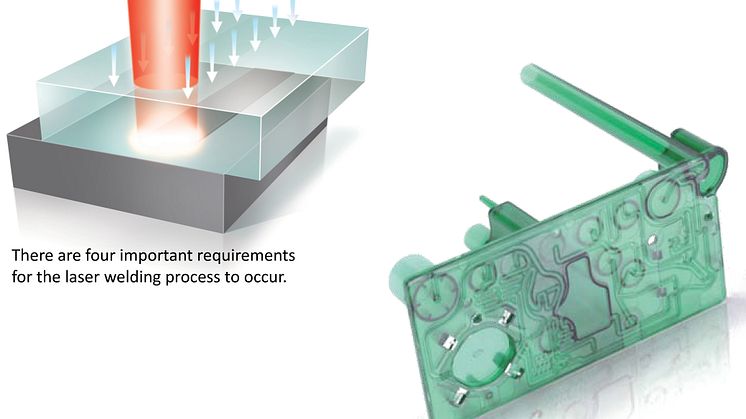

Laser plastic welding is a method of bonding two or more thermoplastic components together. Although there are many methods for joining thermoplastics, laser plastic welding has a few clear advantages: higher joining quality, minimal resulting flash or particulates, higher quality controls, less stress to the component and the ability weld complex and intricate shapes.