Trioworld’s circular solution for plastic aprons is being introduced in Region Stockholm

Trioworld recycles plastic aprons at Region Stockholm hospitals and delivers new ones in a circular solution for protective equipment in healthcare.

Trioworld recycles plastic aprons at Region Stockholm hospitals and delivers new ones in a circular solution for protective equipment in healthcare.

Trioworld, a leading producer of innovative, high-performance plastic film solutions in Europe and North America, has released its annual sustainability report.

Trioworld's six divisions become seven as an adjustment to accelerating growth in line with the M&A strategy as well as the increasing focus on circular solutions for plastic film and expanded recycling capacity.

Among the Trioworld highlights in the FACHPACK stand are a new packaging product development for wet wipes made from beverage carton recycling waste and PCR LDPE as well as hard-wearing stretch hoods with 70% recycled content.

Trioworld, a leading producer of innovative, high-performance plastic film solutions, has released its eighth annual sustainability report. Some of the highlights during the year are the extensive share of post-consumer recycled (PCR) content in the product portfolio, the expansion of the company’s recycling capabilities, and the launch of an upgraded safety culture.

Trioworld, a leading producer of innovative, high-performance plastic film solutions in Europe and North America, is proud to announce that its target set with the overall aim of achieving net-zero greenhouse gas (GHG) emissions across the value chain by 2050 has been verified by the Science Based Targets initiative (SBTi).

Trioworld launched the first ever Post-Consumer Recyclates (PCR) based bale wrap in Agritechnica 2019, the world’s largest agricultural exhibition. With more than five million bales successfully wrapped in high-performance bale wrap made of recycled content since then, Trioworld now displays a full assortment of premium products for baled silage with recycled content at Agritechnica 2023.

Trioworld, the leading producer of innovative and sustainable high-performance plastic packaging solutions in Europe and North America with its head office in Sweden, has published its seventh annual sustainability report. Highlights during the year are, among many, the EcoVadis Platinum rating, the commitment to the Science Based Targets initiative and the significant investment in expanding the

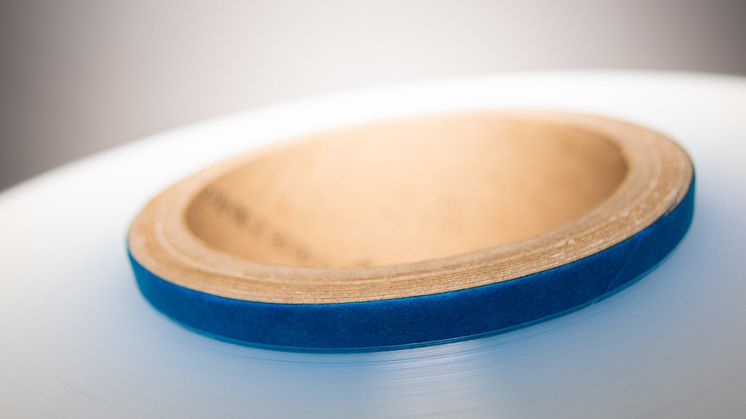

Circular and high performing: the new stretch film, Katan-Ex Loop30, makes it easy to switch to a more sustainable option.

Trioworld Group has signed an agreement to acquire the Canadian based Malpack Ltd. and US based Malpack Corp. (collectively, Malpack), a leading player in solutions for high-performance stretch film in the transit packaging segment. Malpack supports customers in the areas of distribution, beverage, food, consumer goods, e-commerce, and other industrial packaging.

Trioworld is proud to announce that it has received EcoVadis Platinum, the highest-level of recognition from EcoVadis, a leading provider of business sustainability ratings, for the second consecutive year.

Trioworld und große nordische Agrargenossenschaften unternehmen einzigartigen Schritt zur Reduzierung der Klimaauswirkungen von Ballenverpackungen Gemeinsam mit drei großen nordischen Agrargenossenschaften stellt Trioworld den Ballenwickelfolienmarkt in Schweden, Norwegen und Dänemark auf rezyklatbasiertes Material um, um die Klimaauswirkungen der Landwirtschaft zu reduzieren.

Trioworld and major Nordic agricultural cooperatives take a unique step to reduce bale wrap climate impact Together with major Nordic Agricultural Cooperatives, Trioworld will increase the pace to turn the bale wrap market over from virgin to recycled material in Sweden, Norway, and Denmark to reduce the climate impact from agriculture in the Nordics.

Trioworld wins Packnorth Award 2022 for recycled flexible food packaging Today Trioworld was awarded the Packnorth Award in the category ‘Food packaging’ for the first Post-Consumer Recycled (PCR) plastic film, approved for frozen food packaging.

The fundamental idea for Moelven has for 120 years been the same: To use natural resources to the fullest. Now they have achieved yet another milestone by making the switch to a Trioworld Loop packaging with 50% post-consumer recycled material.

Packaging is never more sustainable than its ability to do its primary purpose

If the timber is not protected or transport safety is compromised, th

Trioworld Group has signed an agreement to acquire the British company Quality Films LTD (Quality Films), a strong player in solutions for high-performance stretch film for load security. Quality Films supports customers in the areas of distribution, beverage, food, and other industrial packaging.

Another step on Trioworld's road to a sustainable future accomplished

A top-notch high performance stretch film and at the same time sustainable? That's Trioloop blown coex with 30% PCR, the newest addition to our sustainable portfolio. Top-notch, because of its blown technology, providing high puncture resistance and the best load unit stability. And sustainable because of PCR, post-consumer

Together with Lidl Sweden, Trioworld is launching the first post-consumer recycled (PCR) plastic film, approved for frozen food packaging when Lidl introduces the innovative solution with their cinnamon buns and cardamum buns in Sweden this week.

Trioworld has raised its sustainability target for use of PCR (Post-Consumer Recyclates) to 30 percent by 2025. By increasing the share of PCR in its products, Trioworld levels up its overall sustainability ambition and the circularity of plastics in the society. Previously, the target of 30 percent included both PCR and PIR but will now be fully achieved solely with PCR by 2025.

The fundamental idea for Moelven has for 120 years been the same: To use natural resources to the fullest. Now they have achieved yet another milestone by implementing Trioworld Loop packaging with 50% post-consumer recycled material. This is done both without compromising the quality and without increasing the thickness of the plastic.