Press release -

BPW reinvents the running gear for trailers: Fully digitalised modular concept for on- and off-road use

- Presentation of the new ECO Air running gear at the Bauma trade show in Munich

- Born digital: digital services from configuration to aftermarket service

- A single running gear solution for on-road and off-road; ideal for the construction industry

- 5+3 years warranty on axle, suspension, integration, hub and bearings - throughout Europe

Wiehl, 19.02.2019 --- With a platform for running gears that has been thoroughly redesigned, BPW now covers both on-road and off-road applications. This means that running gear can be configured for trailers that can be used just as easily and efficiently on the road as on the construction site. The highlight is a "digital DNA" that accompanies the vehicle throughout its life with intelligent services.

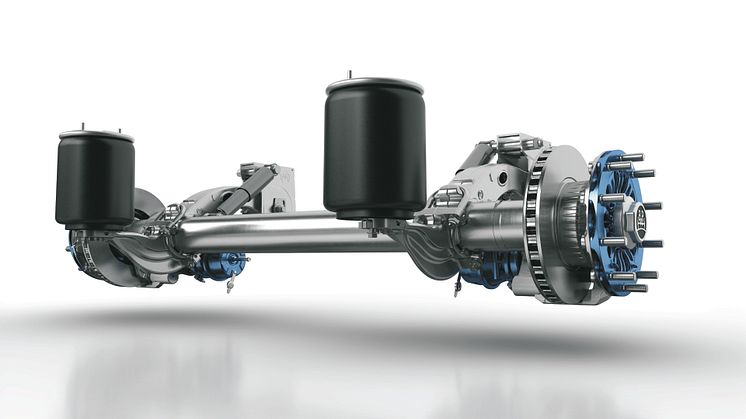

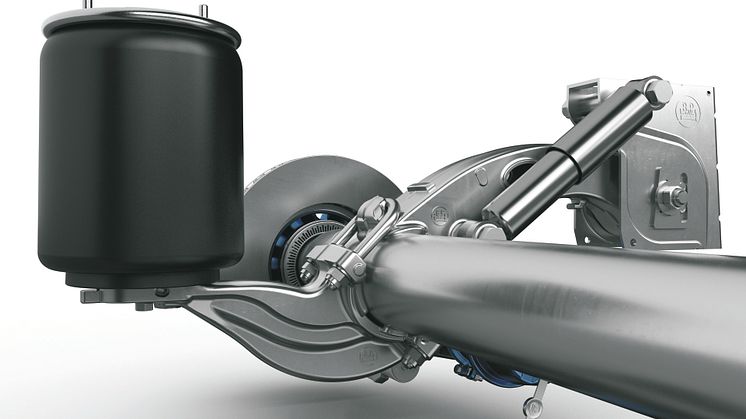

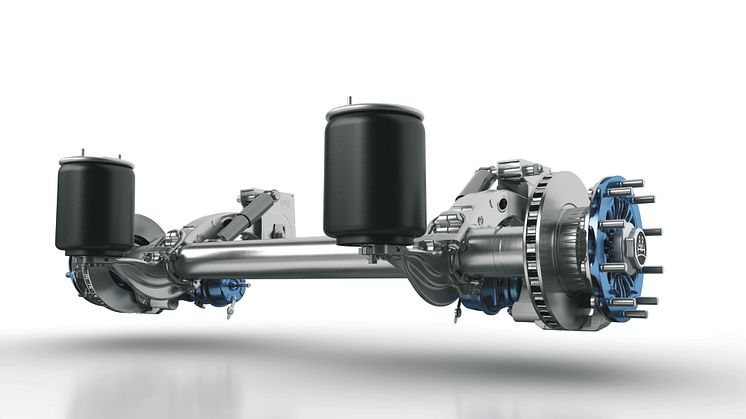

With the new ECO Air running gear, BPW has pulled off the feat of using fewer components to create an even broader range of variants – and to make the chassis more robust and even lighter at the same time. With ECO Air, BPW has for the first time realised its maintenance-friendly clamped integration of the air suspension on a round axle beam – without having to resort to additional shaped elements. A patented laser process generates a three-dimensional profile in the components, which reliably interlocks them while remaining dismountable. BPW has already been successfully using this laser technology for two years: it has proven itself in the 9-ton "ECO Air Compact HD" chassis even in the most demanding off-road applications.

When designing the ECO Air modular running gear system, BPW also had the requirements of the construction industry in mind: Running gears for on-road and off-road applications are now based on a single platform. The modular, clamped design of the BPW air suspension means that only the defective components need to be replaced as required during repairs. The modular architecture with standardized intelligent components allows vehicle manufacturers to purchase BPW chassis as a kit and assemble the desired variant of the components on site. Using the example of a medium-sized vehicle manufacturer, BPW has demonstrated that its average lead times can be reduced from ten days to up to two hours.

BPW underlines the robustness of the running gear under all operating conditions with its guarantee promise: It is valid for five plus three years on the axle, suspension, integration, hub and bearings as well as three years on the bellows, shock absorber and brake cylinder - and is granted throughout Europe.

Born digital: Lifelong digital DNA, development cycles eliminated

BPW has developed its new generation of running gear digitally from the ground up: Each component is systematically provided with information on all its technical properties and possible combinations. This means that the running gear can be configured online in the shortest possible time. The vehicle manufacturer can integrate a CAD model of the running gear directly into his CAD design. The intelligent system avoids errors in the configuration and accelerates the entire design and ordering process. An order can be triggered online from the configuration, which equips the chassis with a lifelong "digital DNA": It automatically controls production and delivery by BPW and also accompanies the running gear during maintenance and spare parts service.

The new modular concept and integrated digitization allows BPW to virtually eliminate conventional development cycles for running gears: Architecture and components are no longer redesigned every five to seven years, as is customary in the industry, but are now subject to a permanent innovation process.

ECO Air is already being used by pilot customers and will go into series production in May.

BPW will be showing the new running gear from 8 to 14 April at Bauma in Munich in the open-air area at Stand FN.827/9.

Topics

Categories

About BPW Bergische Achsen Kommanditgesellschaft

BPW Bergische Achsen Kommanditgesellschaft is the parent company of the BPW Group. With over 1,600 employees, including around 120 trainees, the family-owned company has been developing and producing complete running gear systems for truck trailers and semi-trailers at its headquarters in Wiehl since 1898. BPW’s technologies include axle systems, brake technology, suspension and bearings. BPW’s trailer axles and running gear systems are in use in millions of vehicles around the world. An extensive range of services also offers vehicle manufacturers and operators the ability to increase the efficiency of their production and transport processes. www.bpw.de/en

About the BPW Group

The BPW Group researches, develops and manufactures everything needed to ensure that transport keeps moving and is safe, illuminated, intelligent and digitally connected. With its brands BPW, Ermax, HBN, HESTAL and idem telematics, the company group is a preferred system partner of the commercial vehicle industry around the globe for running gear, brakes, lighting, fasteners and superstructure technology, telematics and other key components for trucks, trailers and buses. The BPW Group offers comprehensive mobility services for transport businesses, ranging from a global service network to spare parts supply and intelligent networking of vehicles, drivers and freight. The owner-operated company group currently employs 7,200 staff in more than 50 countries and achieved consolidated sales of 1.48 billion euros in 2017. www.bpw.de/en