Press release -

IAA 2018: BPW presents innovative electro-hydraulic auxiliary steering system Active Reverse Control

- Simple and low-maintenance system

- Improved trailer steering functionality now also available in reverse

- Vehicle can be manoeuvred quicker and automatically in reverse

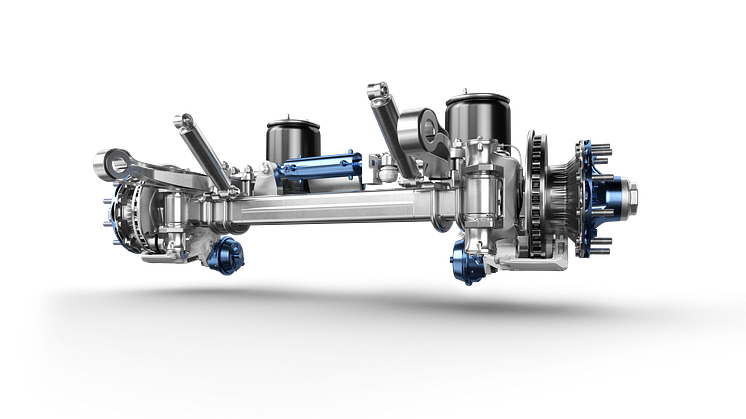

BPW will be showcasing its new electro-hydraulic auxiliary steering system Active Reverse Control at IAA Commercial Vehicles 2018 in Hanover (Hall 26, Stand C31). This innovative system supports the steering functionality of trailers and is light, cost-effective and low-maintenance. This independent solution does not require approval, is particularly easy to install and can also be retrofitted depending on the chassis type.

Loading and unloading often involves manoeuvring in tight spaces – in particular for vehicles such as tankers that collect milk from farms or trucks that deliver drinks to supermarkets. This takes a great deal of time and frequently results in damage to the vehicle. Until now, mechanical self-steering axles could only be of assistance when the vehicle was travelling forwards. The innovative auxiliary steering system from the BPW Group now also provides steering functionality – and therefore trailer manoeuvrability – during reverse manoeuvres. The vehicle can therefore be manoeuvred quicker and automatically in reverse.

Collisions can also be avoided: ‘Until now, this function could only be achieved with active steering and the entire vehicle concept usually had to be adapted to this. Such solutions are complex and expensive,’ explains Bernhard Rossenbach, head of product management at BPW. ‘Vehicles with active steering systems are customised solutions. We wanted to offer a product that complements our portfolio perfectly and at the same time is easy for customers to install and to integrate in their existing vehicle concept.’

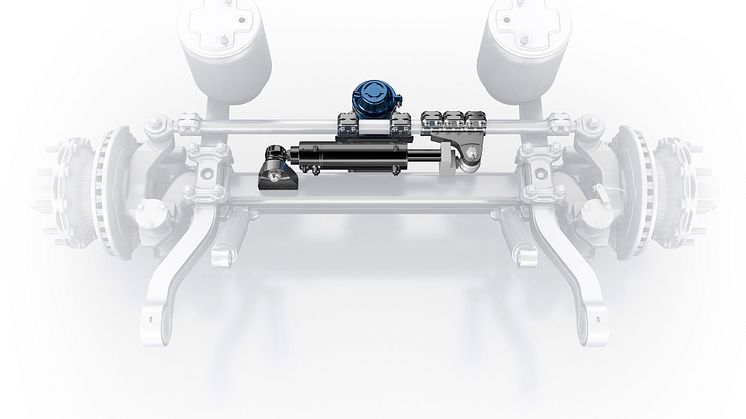

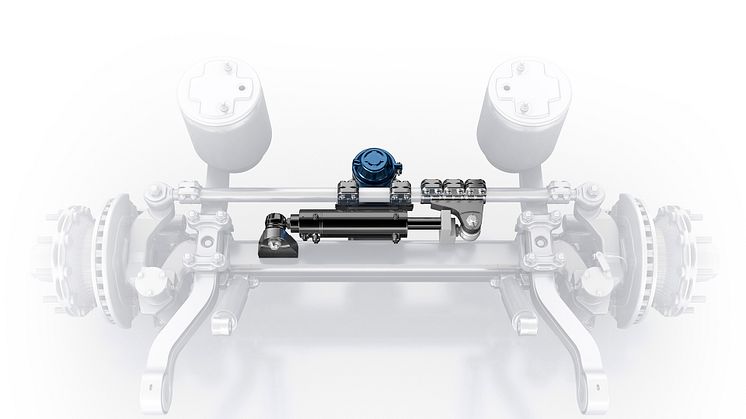

The new system from BPW consists of a control unit, a hydraulic unit and a steering cylinder with an integrated steering angle sensor. The steering cylinder is fitted locally on the self-steering axle and is operated via the hydraulic unit with reservoir. The steering operates fully automatically but can also be operated manually with a remote control: as soon as the driver engages the reverse gear, the steering system is activated via the reversing lights and the rotational speed and rotational direction sensor. The control unit uses innovative sensor technology that automatically detects the direction and angle of steering. The auxiliary steering system is only activated during reverse travel. During forwards travel, the system is passive and the steering is performed mechanically via the self-steering action.

Topics

Categories

About BPW Bergische Achsen KG

BPW Bergische Achsen KG is the parent company of the BPW Group. With more than 1,600 employees, including around 120 trainees, the family-run company has been developing and producing complete running gear systems for truck trailers and semi-trailers at its headquarters in Wiehl since 1898. BPW’s technologies include axle systems, brake technology, suspension and bearings. BPW’s trailer axles and running gear systems are in use in millions of vehicles around the world. An extensive range of services also provides vehicle manufacturers and vehicle operators with the opportunity to increase economic efficiency in their production and transport processes. www.bpw.de/en

About the BPW Group

The BPW Group, based in Wiehl, Germany, is a dependable international mobility and system partner for the transport industry, serving as a one-stop shop for innovative solutions. Its portfolio embraces axles, suspension systems and brake technologies (BPW), locking systems and bodywork technology (Hestal), lighting systems (Ermax), composite technologies (HBN-Teknik), and user-friendly telematics applications for trucks and trailers (idem telematics). BPW Group’s technologies and services support manufacturers’ cost-effective workflows and enable vehicle operators to manage their fleets efficiently by maximising the transparency of loading and transport processes. The owner-managed BPW Group encompasses 70 companies worldwide and employs around 7,000 people. www.bpw.de/en