Press release -

AURUNA® 5750: High-quality gold-silver alloy for cost-efficient coatings

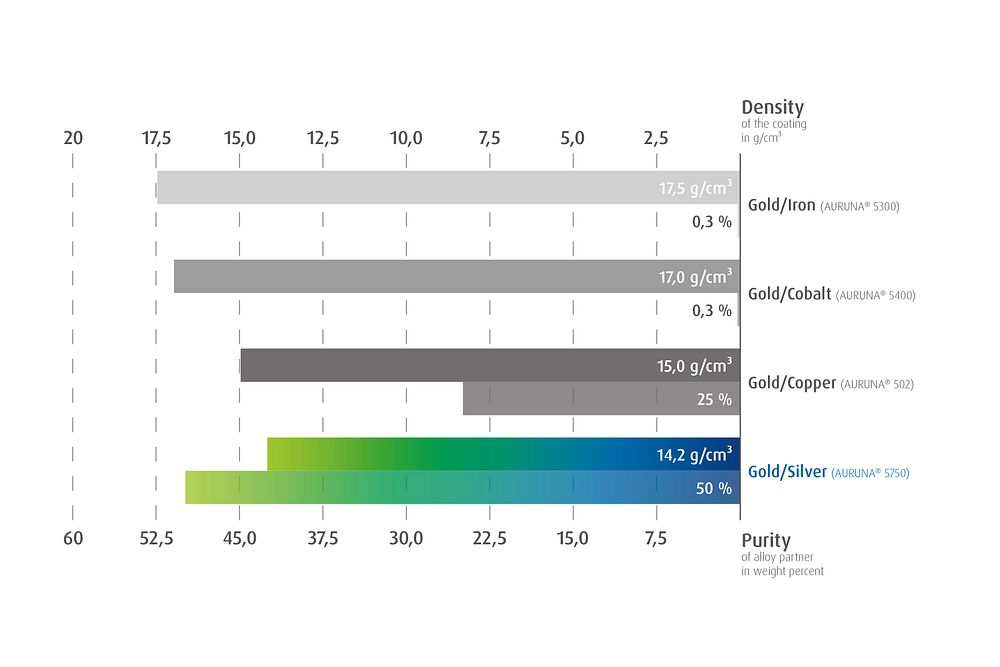

With AURUNA® 5750, the business unit Metal Deposition Solutions (MDS) of the Umicore Group now offers an innovative gold-silver electrolyte that appears to be unrivaled in terms of quality in electroplating technology. Its alloy properties read like a specification sheet from the industry for high-quality and functional gold plating. At the same time, the gold content of only 50 % makes AURUNA® 5750 an extremely cost-efficient solution.

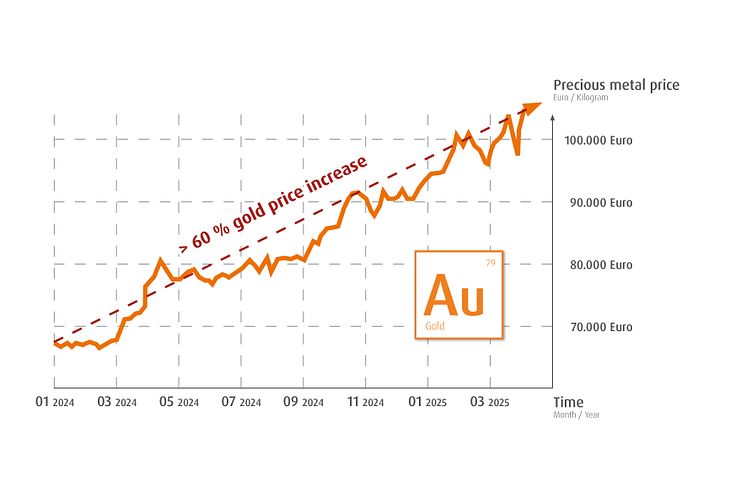

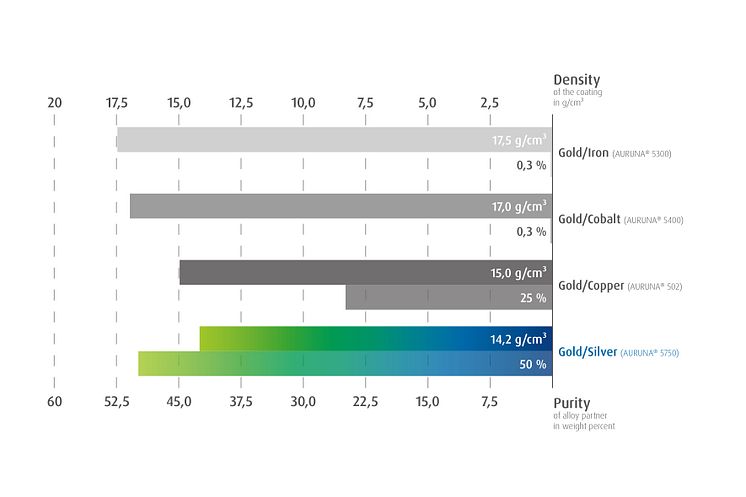

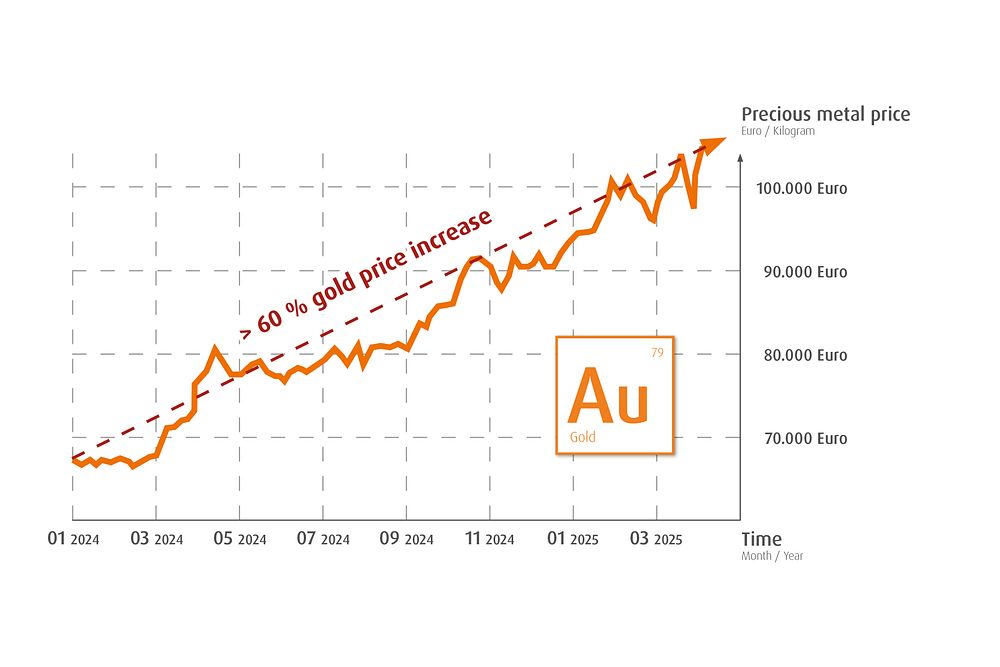

In recent months, the price of gold has risen sharply. This drastic price increase has far-reaching consequences for all products with gold plating, regardless of whether they are decorative or technical applications. Such products are becoming significantly more expensive to manufacture and are increasingly unattractive to many end customers due to the associated cost increases. Umicore MDS has responded to this challenge by developing AURUNA® 5750, a gold-silver electrolyte that enables 12-carat intermediate and final layers. These layers contain equal amounts of both precious metals. Due to the different densities of the two precious metals, this allows savings of around 60% in precious metal costs compared to pure gold layers.

Outstanding characteristics

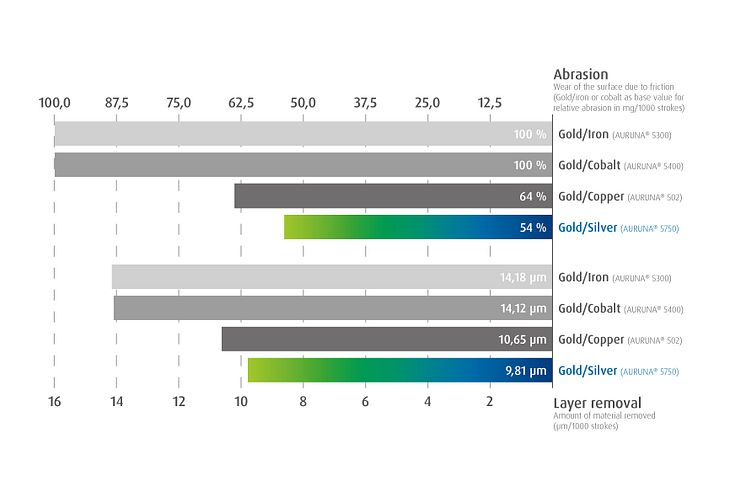

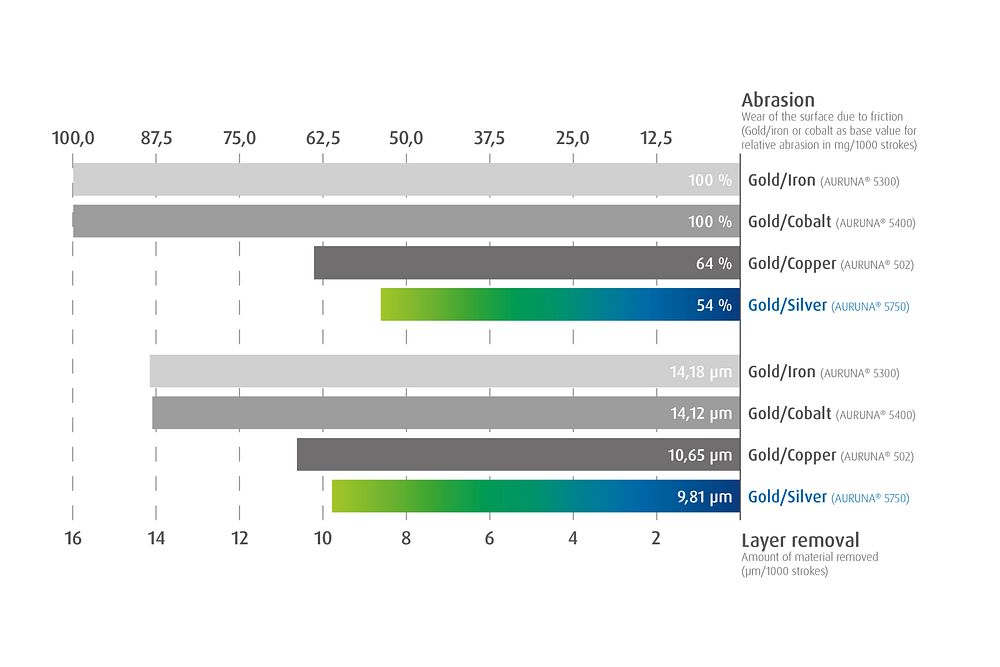

AURUNA® 5750 not only impresses with its cost efficiency. The deposited layers also impress with their ductility, which is atypical for hard gold (220 HV / hardness according to Vickers), and their seemingly contradictory, extraordinary abrasion resistance. This is confirmed in the Bosch-Weinmann test, in which very low abrasion and layer removal values are achieved compared to conventional gold alloys due to the high degree of hardness and the lubricating properties of the silver. Compared to gold-iron or gold-cobalt alloys, which also lead to a gold-yellow deposition, the abrasion values of AURUNA® 5750 are almost halved.

Versatile application options

AURUNA® 5750 is not only the first choice for cost-optimized gold plating as an elegant pastel gold final layer. It is also suitable for protective and color-preserving intermediate layers, for example for jewelry or plug contacts where a more intensive gold tone is desired. The coatings are particularly flexible and resistant due to the high silver content. Even with thicker layers, the shine is completely retained.

Environmentally friendly and easy to use

Another advantage of AURUNA® 5750 is its low environmental impact. The electrolyte contains no toxic heavy metals and therefore meets the strict technical standards of the RoHS Directive. Nevertheless, the alloy provides reliable protection against corrosion. The uniform and stable plating also extends the service life of the plated objects.

The electrolyte is easy to handle and insensitive to metallic impurities - regardless of whether AURUNA® 5750 is used for rack or barrel goods. Due to the wide range of possible applications, different layer thicknesses are required. Care has therefore been taken to ensure that crack-free deposition is possible up to a thickness of 10 µm. If very thin layers are required, an even more cost-effective variant with a low gold content can be used, resulting in additional savings.

Fast development time

"With AURUNA® 5750, we are once again setting new standards in electroplating technology," says Martin Stegmaier confidently. The Division Manager of Decorative Applications is delighted to be able to offer his customers this cost-efficient gold-silver electrolyte so quickly and explains: "The rapid development was made possible by our decades of experience with related alloys from electroforming. This established base makes AURUNA® 5750, with its truly outstanding characteristics, a future-proof choice for the electroplating industry."

Prototype coating and economic efficiency calculation

With AURUNA® 5750, an innovative gold-silver electrolyte is available as an economical solution for gold plating that meets the highest demands. However, Thilo Kuhn, Director Sales and Marketing, knows that despite its outstanding characteristics, the electrolyte may have to overcome internal hurdles with producers. He explains: "In some cases, time-consuming qualification processes are necessary in order to convert production lines. That's why we offer an uncomplicated prototype coating together with an economic efficiency calculation. This allows us to eliminate any concerns about whether a conversion is actually worthwhile."

Related links

Topics

Categories

About Umicore Metal Deposition Solutions

Umicore's Business Unit Metal Deposition Solutions (MDS) is part of Umicore Group. The business unit harbors two business lines Electroplating and Thin Film Products. MDS is one of the world's leading suppliers of products for (precious) metal-based coating of surfaces in the nano and micrometer range – with the expertise of the two areas, we combine the two highest-quality processes: electroplating and PVD coatings.

MDS's solutions are used in many products for everyday use, and in some cases their production would not be possible without them. Almost all well-known manufacturers in the electronics, automotive, optics and jewellery industries purchase components that have been coated with our Umicore products, either directly or indirectly.

In addition to development and production, Metal Deposition Solutions offers a comprehensive service for its products. This includes not only advice and technical support on site, but also recycling and precious metal management.

Please activate this link for more information on Metal Deposition Solutions

Please activate this link for more information on Umicore Group