Press release -

High-quality cobalt- and nickel-free hard gold plating

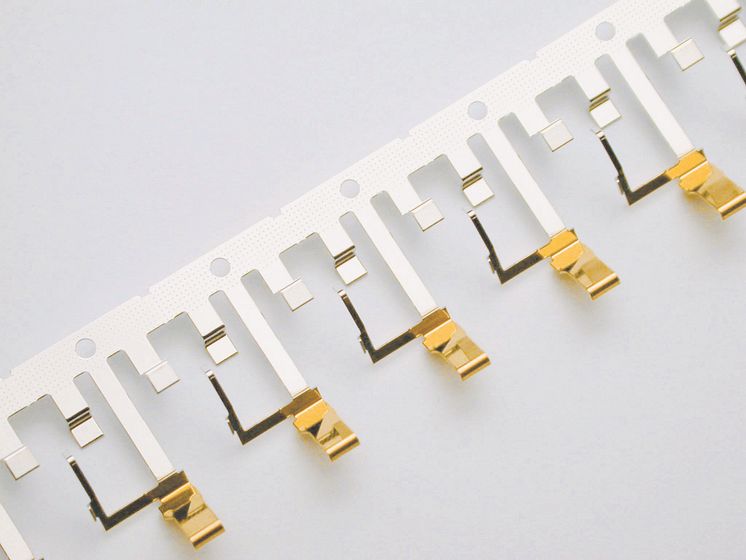

Umicore Metal Deposition Solutions, a leading provider of metal deposition solutions, is pleased to announce the introduction of the new AURUNA® product line. This innovative series offers cobalt- and nickel-free hard gold plating that meets the highest quality standards while providing environmental and ethical benefits. With the new AURUNA® product line, Umicore is setting a new industry benchmark and is underlining its commitment to sustainable and responsible technologies.

Perfect symbiosis of gold and iron

The new AURUNA® gold-iron alloys combine the precious, soft gold with the non-precious, robust iron to form a perfect final layer. This combination is not only aesthetic and functional, but also more sustainable and economical than conventional hard gold compounds with cobalt or nickel. The AURUNA® product line offers an excellent alternative to traditional hard gold alloys, enabling customers to make their processes safer and more environmentally friendly.

Challenges of conventional hard gold alloys

Traditional hard gold alloys contain cobalt or nickel, which entails significant environmental, health and safety (EHS) risks. The extraction and processing of these metals is ethically problematic and highly regulated. In addition, their handling requires high safety standards to minimize health risks. These growing challenges have led Umicore to develop an innovative solution that addresses these issues while meeting the highest quality standards.

Advantages of the new AURUNA® product range

-

Conflict-free sourcing

iron, in contrast to cobalt and nickel, is conflict-free and available in large quantities. This reduces dependence on problematic raw materials and contributes to a more ethically correct and significantly more transparent supply chain. Companies can thus position themselves as responsible players while keeping bureaucratic hurdles to a minimum. -

High availability and cost efficiency

Iron is inexpensive and does not require expensive safety standards for processing. This enables customers to reduce their production costs while improving the safety of their processes. -

Sustainability

cobalt- and nickel-free sourcing and production reduces environmental issues associated with resource extraction. Umicore is committed to environmentally friendly and responsible production and supports its customers in achieving their sustainability goals. -

Excellent plating properties

AURUNA® electrolytes produce crack-free, ductile and low-porosity layers that are highly resistant to abrasion and chemical attack. This ensures a long durability and high reliability of the coated products.

AURUNA® 313, AURUNA® 5300 and AURUNA® 215 (PALE)

The new AURUNA® 313, which serves as the basis for the product range, is based on the AURUNA® 311, which has been successful on the market for over 40 years and is in no way inferior to it. Like its forerunner, the halide- (chloride- or fluoride-), nickel- and cobalt-free AURUNA® 313 is the first choice for the direct gold plating of difficult-to-activate stainless steels (e.g. chromium-nickel steels, molybdenum-containing steels or nickel-based alloys) and other passive materials. This innovative solution enables customers to achieve high-quality and long-lasting coatings that meet the most stringent requirements.

AURUNA® 5300 was specially developed for barrel and rack operation and enables RoHS-compliant coatings. This makes it particularly attractive for decorative applications such as jewelry and writing instruments, not only because its coatings are nickel- and cobalt-free and therefore allergen-free. Alternatively, this gold-iron electrolyte can also be used for technical products.

AURUNA® 215 is an exceptionally color-constant variant. The deposition color (1N - 2N) is independent of the pH value and current density over a wide working range. The addition of indium also ensures that there are no color nuances even with different production batches. This electrolyte is also available in a very noble-looking, pale yellow (1N) version as AURUNA® 215 Pale.

Outlook on future expansions

Umicore Metal Deposition Solutions plans to continuously expand the AURUNA® product line to meet the growing demands and specific needs of its customers. ‘For special scenarios or requirements that demand an electrolyte that meets an industry standard (e.g. ASTM standards), is cost-optimized, faster or deposits with higher layer thicknesses, we have earmarked further gold-iron electrolytes in our portfolio,’ says Martin Stegmaier (Division Manager for PGM and Decorative Precious Metal Applications), describing the current research activities on the product line.

With this strategic expansion of the AURUNA® product range, Umicore is emphasizing its commitment to always being at the forefront of technological innovation and offering its customers the best solutions for their specific challenges.

Related links

Topics

Categories

About Umicore Metal Deposition Solutions

Umicore's Business Unit Metal Deposition Solutions (MDS) is the business headquarters for the two established business lines Electroplating and Thin Film Products within the Umicore Group. Metal Deposition Solutions is one of the world's leading suppliers of products for (precious) metal-based coating of surfaces in the nano and micrometer range – with the expertise of the two areas, we combine the two highest-quality processes: electroplating and PVD coatings.

The business unit's solutions are used in many products for everyday use, and in some cases their production would not be possible without them. Almost all well-known manufacturers in the electronics, automotive, optics and jewellery industries purchase components that have been coated with our Umicore products, either directly or indirectly.

In addition to development and production, Metal Deposition Solutions offers a comprehensive service for its products. This includes not only advice and technical support on site, but also recycling and precious metal management.

For more information: mds.umicore.com