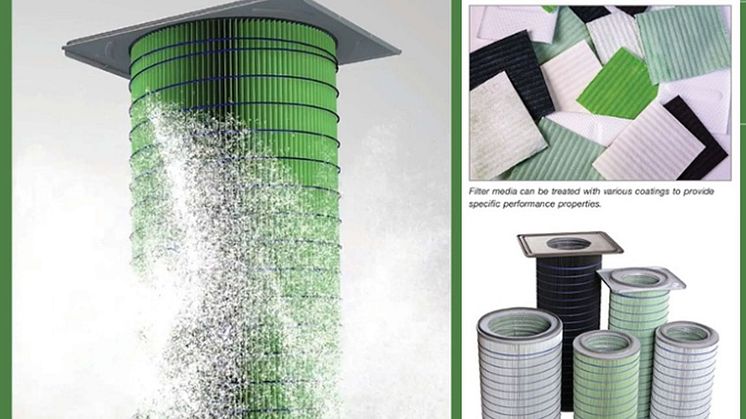

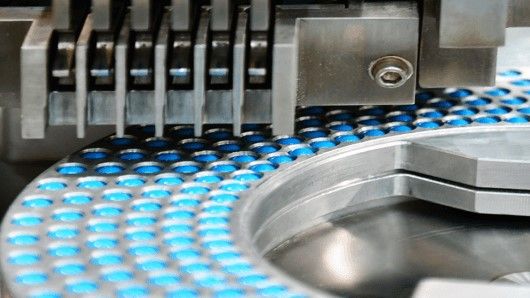

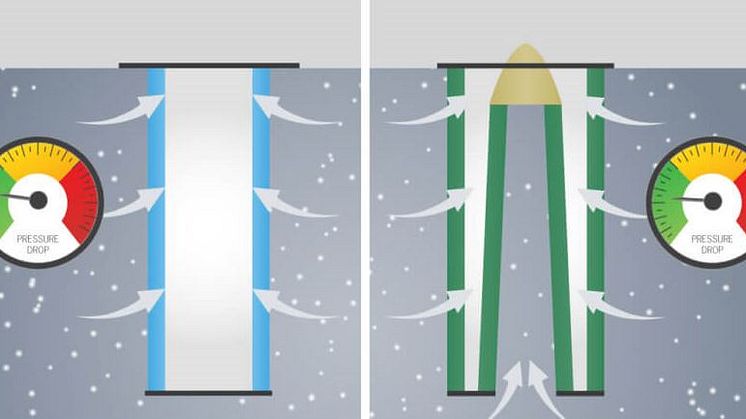

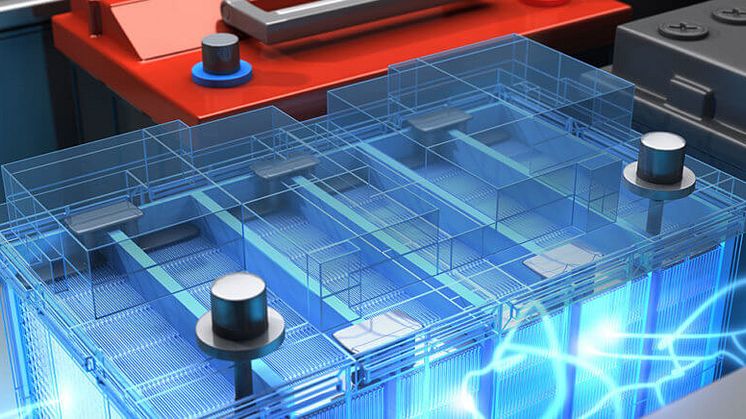

For more than half a century, Camfil has been helping people breathe cleaner air. As a leading manufacturer of premium clean air solutions, we provide commercial and industrial systems for air filtration and air pollution control that improve worker and equipment productivity, minimize energy use, and benefit human health and the environment. We firmly believe that the best solutions for our customers are the best solutions for our planet, too. That’s why every step of the way – from design to delivery and across the product life cycle – we consider the impact of what we do on people and on the world around us. Through a fresh approach to problem-solving, innovative design, precise process control, and a strong customer focus we aim to conserve more, use less, and find better ways – so we can all breathe easier.

The Camfil Group is headquartered in Stockholm, Sweden, and has 29 manufacturing sites, six R&D centers, local sales offices in 35+ countries, and 5,700 employees and growing. We proudly serve and support customers in a wide variety of industries and in communities across the world. To discover how Camfil USA can help you to protect people, processes, and the environment, visit us at www.camfil.us.