News -

A Unique Approach Accelerating the Shift to Smart Factories Yamaha Motor Newsletter (Aug. 4, 2021 No. 90)

Making factories smarter by using digital data to transform the work processes at manufacturing sites, improve quality, and enhance productivity is a movement underway at manufacturing and production facilities across a wide range of industries.

Yamaha Motor is no exception and is moving forward with its own smart factory initiatives by incorporating proprietary technologies. In this issue, we introduce the highly original approach the company is taking.

What Is a Smart Factory for Yamaha Motor?

Yamaha’s compact AGVs can adapt to changes in the same manner as toy blocks

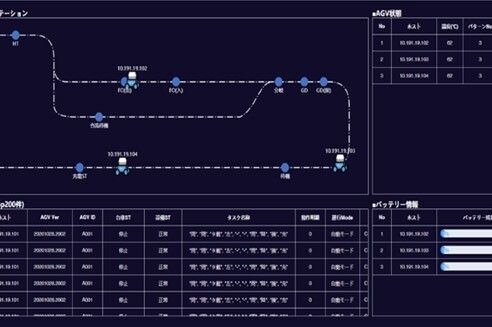

The unmanned vehicles pictured above transport engine parts around Yamaha Motor’s factory premises and are smart factory vehicles developed by

eve autonomy, Inc., a joint venture between Yamaha Motor and Tier IV, Inc. By combining Tier IV’s automated driving open-source operating system with Yamaha Motor’s mobility technologies, we are developing a highly versatile, easy-to-operate, and low-cost automated transport solution through real-world operations at production sites.

“In our case, the term ‘smart factory’ may differ a bit from the general understanding,” says Yasumitsu Ibaragi of Yamaha’s Manufacturing Technology Center. If a smart factory is generally considered to bring changes to the production site through modern developments such as Industry 4.0, AI, and IoT, Ibaragi posits that, “Yamaha Motor’s style with smart factories is to position them as the foundation of our theoretical-value-based production* activities that we have long had in place at our worksites. We look to grasp the differences and variations that emerge between the theoretical ideal and the actual values in real time. We have set this as the goal and definition of our smart factory efforts and we are accelerating our initiatives to that end.”

*Theoretical-value-based production: An improvement method that classifies all work related to production into work with and without value, and seeks to raise the ratio of work with value toward the theoretical ideal.

People Take the Lead in Yamaha Smart Factories

Each AGV carries information for creating a smart factory

It took some trial and error before such approaches became fully organized and methodical. Behind this were requirements unique to motorcycle production, such as high-mix, low-volume production and seasonal fluctuations. “Approaching smart factories from a methodology perspective did not take root and we did not see results improve,” confesses Ibaragi. So, Yamaha instead returned to the basic principle that the real problems that need fixing can be found on the factory floor and worked on establishing its own definitions, methods, and solutions.

One example of this effort is the AGV (automated guided vehicle). Increasing the part lots for transport in order to reduce labor costs and avoid purchasing numerous expensive AGVs would only result concealing the heart of the issue itself. Another issue discovered was that further investments in short-distance transport would yield fewer beneficial effects. What factories needed was a compact and low-cost AGV that could be smoothly integrated into factory processes, be easy to operate, and be capable of adapting to changes with a modular construction similar to a set of toy blocks. Today, at Yamaha Motor’s casting facility for manufacturing motorcycle wheels, small AGVs developed in-house based on our electric wheelchairs make their way around the factory floor, loaded with parts.

Volume per hour, quality and inventory levels, transport frequency, and the like are all decided by the work done at Yamaha’s manufacturing departments. “The causes that lead to our results are analyzed and visualized by integrating them with digital tools, and I think it is important for people working on our factory floors to use the results of these analyses to work on addressing our issues and making improvements going forward,” says Ibaragi. “In the end, people remain the star actors of smart factories at Yamaha. Making our facilities smarter helps people focus more on work with value, which not only helps individuals grow but also the company. That, I think, represents a real achievement.”

Unmanned Vehicles at Work at Yamaha Motor Factories

eve autonomy, Inc. provides unmanned solutions for transport at factories via automated driving

|

Message from the Editor “It’s difficult to produce the benefits of smart factories just by connecting the major arteries. What was really needed were all the ‘capillaries,’ so to speak,” says Ibaragi. Yamaha Motor’s manufacturing and production sites are aiming to centrally manage data on people, equipment, and products across the various processes involved with gathering market information, design, and manufacturing. These worksites are now employing new tools, such as these compact AGVs, as “capillaries” that reach every corner of the factory. Maiko Kawai |