Press release -

Achieved a 93.8% Methane Slip Reduction Rate in Onshore Tests and Received the Statement of Fact for the First Time in the World

Hitachi Zosen Corporation (hereafter, Hitachi Zosen), Mitsui O.S.K. Lines, Ltd. (hereafter, MOL), and YANMAR POWER TECHNOLOGY CO., LTD. (hereafter, Yanmar PT) achieved a 93.8% of reduction rate (at an engine load rate of 100%) in the development of the technology to reduce the methane slip※1 from LNG-fueled vessels through catalyst and engine improvements (hereafter, this project). This project was adopted by the New Energy and Industrial Technology Development Organization (hereafter, NEDO), and the achievement of the reduction rate was confirmed by ClassNK (NK) through the Statement of Fact (SOF) for the first time in the world.

The project aims to achieve a 70% or more reduction in methane slip from LNG-fueled vessels by combining methane oxidation catalyst and engine improvements during the six-year period from fiscal 2021 to fiscal 2026. It also aims to socially implement technology for reducing methane slip, which has not been established even on land, in the field of marine transportation, ahead of the rest of the world.

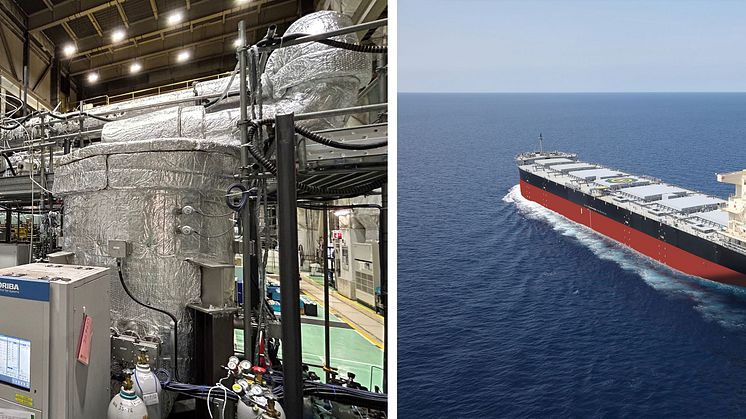

In 2022, Hitachi Zosen and the Yanmar PT developed the “Methane Oxidation Catalyst System”※2, which reduces methane slip by oxidizing methane emitted from marine engines fueled by LNG and received NK's “Approval in Principle”※3. In December 2023, a land-based test achieved a reduction rate of 93.8%, far exceeding the target of more than 70%, by combining engine improvements with EGR※4 and a methane oxidation catalyst system, and the vehicle was the first in the world to receive the SOF from NK. The results were highly evaluated and passed the screening by NEDO for selection for continued support in February 2024. The demonstration test will start in the autumn of 2024 on a large coal carrier (vessel name: REIMEI) operated by MOL.

In July 2023, the International Maritime Organization (IMO) adopted a new plan to achieve zero emissions by around 2050, and the Maritime Cluster※5 has been developing new technologies to convert ships' fuels into new fuels that emit less greenhouse gases.

As for fuels for ships, methanol, ammonia and hydrogen are being considered as future option. However, the widespread use of LNG fuel is currently being promoted as a low emission fuel that is feasible at present. Nevertheless, while LNG fuel has the potential to reduce CO2 emissions, methane slip is an issue.

Hitachi Zosen, MOL, and Yanmar PT will work to quickly establish a technique for reducing methane slip through this project and actively contribute to reducing greenhouse gases emissions in the global marine transportation sector.

Outline of this project

- Public offering: National Institute of New Energy and Industrial Technology Development (NEDO)

- Project name: Green Innovation Fund Project "Development of Next-Generation Ships" Project

- Implementor:

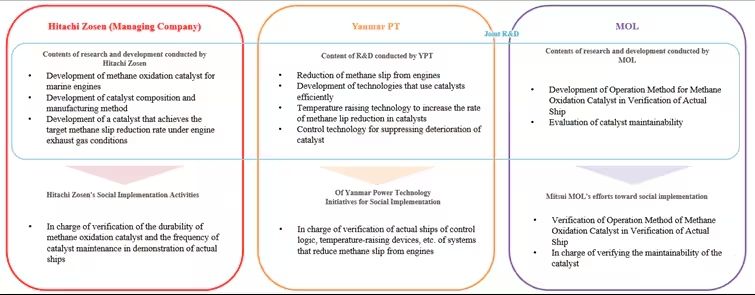

(Managing Company) Hitachi Zosen Corporation. (Osaka Prefecture, President and COO: Michi Kuwahara)

(Joint Implementer) Mitsui O.S.K. Lines, Ltd. (Tokyo, President and CEO: Takeshi Hashimoto),

YANMAR POWER TECHNOLOGY CO., LTD. (Osaka Prefecture, President and CEO: Tomohisa Tao) - R&D Theme: Development of technology to reduce methane slips from LNG-fueled vessels by improving catalysts and engines.

- Implementation period: FY2021 to FY2026

Roles of each party in this project and initiatives for social implementation

※1Some of the methane in LNG is exhausted into the atmosphere as unburned methane. Methane has a higher greenhouse effect compared with CO2, and methane slip reduction is also required from the viewpoint of GHG reduction.

※2A methane oxidation catalyst is placed in the exhaust pipe of an LNG fuel-engine-generator containing unburned methane, and methane is oxidized on the catalyst to reduce methane slip.

※3Equipment and systems with no or very few precedents are examined by classification societies in terms of feasibility and safety in the light of current regulations and guidelines and issued as proof of compliance with requirements.

※4Exhaust Gas Recirculation, a technology that recirculates engine exhaust gases to reduce unburnt methane slip and NOx.

※5Industries related to shipping, shipbuilding, and marine industry.

Related links

Topics

Categories

Note: Information contained in the news release is valid at the time of publication and may differ from the most recently available information.

[Inquiries for further information]

Corporate Communications, Yanmar