Press release -

Design Approved for World's First Methane Oxidation Catalyst System

Promoting Development of Technology to Reduce Methane Slip on LNG-fueled Vessels Toward Further Reducing Environmental Impact

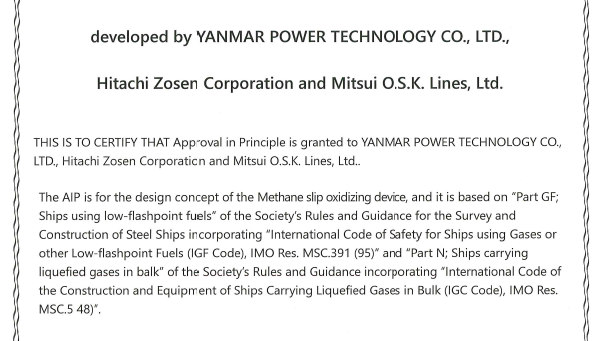

Hitachi Zosen Corporation, Mitsui O.S.K. Lines, Ltd. (MOL), and Yanmar Power Technologies Co. (YPT), have received Approval in Principle for the Methane Oxidation Catalyst System (Note 1) from Nippon Kaiji Kyokai (ClassNK). The system reduces methane slip by placing a methane oxidation catalyst in an LNG fuel engine and oxidizing the methane. This is the first time in the world that a methane oxidation catalyst system has received Approval in Principle (Note 2).

This project was adopted by the New Energy and Industrial Technology Development Organization (NEDO) as "Development of Methane Slip Reduction Technology from LNG Fueled Vessels by Improving Catalysts and Engines" (Note 3) under the Development of Next-generation ship Project of the Green Innovation Fund (Note 4). Hitachi Zosen and YPT created the system design with MOL and Namura Shipbuilding Co., Ltd. set to build the actual demonstration vessel and design the system's installation. The companies are working together closely to conduct risk assessments and implement other measures. This time, it was confirmed that the proposed system meets the requirements of the International Code of Safety for Ship Using Gases or Other Low-flashpoint Fuels (IGF Code) (Note 5) and other regulations.

The project aims to further reduce the environmental impact of LNG fuel engine by achieving a methane slip reduction rate of more than 70% over a six-year period from FY2021 to FY2026 by combining a methane oxidation catalyst and engine improvements and verifying the design concept in actual vessels. The Approval is an important first step toward establishing the technology for this system.

Note1: Methane Oxidation Catalyst System

This system is placed in the exhaust pipes of LNG fuel engines and generators that contain unburned methane, and methane is oxidized on the catalysts to reduce methane slip.

Note2: Approval in Principle

An AiP is issued to equipment and systems that are unprecedented or have very few precedents where the Classification Society has confirmed that the establishment and safety of the equipment and systems meet the current rules and guidelines.

Note 3: Methane slip

In gas engines, a portion of the methane in the LNG fuel is emitted into the atmosphere as unburned methane, via the exhaust. Methane has a higher greenhouse effect than CO2, and methane slip reduction is required to achieve greenhouse gas reductions.

Note 4: Please refer to the following press releases dated October 27, 2021 regarding this project.

Hitachi Zosen

https://www.hitachizosen.co.jp/english/newsroom/news/release/assets/pdf/ENL%20methaneslip.pdf

MOL

https://www.mol.co.jp/en/pr/2021/img/21092.pdf

YPT

https://www.yanmar.com/global/news/2021/10/27/99066.html

Note 5: IGF code

International Code of Safety for Ship Using Gases or Other Low-flashpoint Fuels issued in 2017 to specify safety requirements for ships using gas fuels and low flash point fuels.

Hitachi Zosen

Hitachi Zosen has been supplying NOx removal catalysts and NOx removal systems to domestic and overseas applications for over 50 years. In addition, since 2015, Hitachi Zosen has installed them in marine diesel engines to provide solutions required for air pollution prevention.

Utilizing the technology cultivated as the only manufacturer of both "catalysts" and "marine diesel engines" in Japan, Hitachi Zosen will develop catalysts that oxidize slipped methane in this project. Hitachi Zosen will contribute to the prosperous future of the earth and people.

MOL

MOL is developing various social infrastructure businesses such as marine business and wind energy-related business, centering on the shipping business such as dedicated ships that carry various raw materials and fuels, tankers, and product transport ships such as automobiles. With the world's largest fleet, experience, and technology cultivated over 130 years of history, and a spirit of challenge aiming to create new value, we are contributing to the development of the world economy and environmental conservation. In this project, we aim to further reduce the environmental load of LNG fueled ships by establishing the operation of methane reduction technology on actual ships. We will contribute to the reduction of greenhouse gas emissions from our vessels, the low-carbonization of customers' supply chains such as shippers, and the low-carbonization of society as a whole.

Yanmar

With beginnings in Osaka, Japan, in 1912, Yanmar was the first ever to succeed in making a compact diesel engine of a practical size in 1933. A pioneer in diesel engine technology, Yanmar is a global innovator in a wide range of industrial equipment, from small and large engines, agricultural machinery and facilities, construction equipment, energy systems, marine, to machine tools, and components — Yanmar’s global business operations span seven domains. On land, at sea, and in the city, Yanmar provides advanced solutions to the challenges customers face, towards realizing A Sustainable Future.

For more details, please visit the official website of Yanmar Holdings Co., Ltd.

https://www.yanmar.com/global/...

Topics

Categories

Note: Information contained in the news release is valid at the time of publication and may differ from the most recently available information.

[Inquiries for further information]

Public Relations Group Brand Communication Division, Yanmar Global Expert Co., Ltd.,

TEL: 06-6376-6212 E-mail: newsroom@yanmar.com