Press release -

Yanmar Develops Next-Gen Electric Work Machine Prototype with Enhanced Force Control

Osaka, Japan (November 21, 2023) - Yanmar Holdings Co., Ltd. (Yanmar HD) has unveiled a prototype of a cutting-edge electric work machine with advanced force control at the Construction DX Challenge 2023, organized by the Japanese Ministry of Land, Infrastructure, Transport, and Tourism.

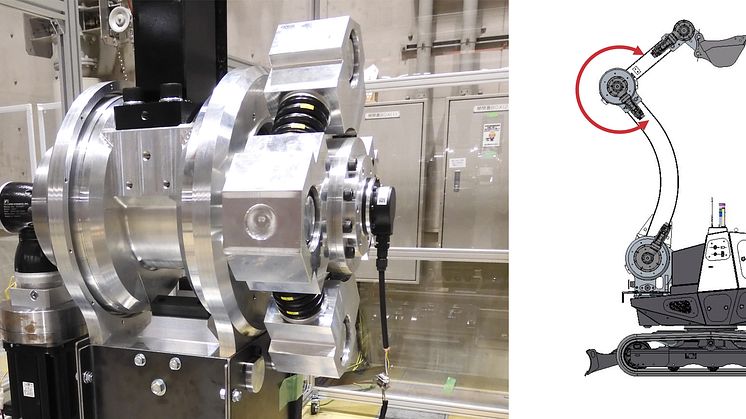

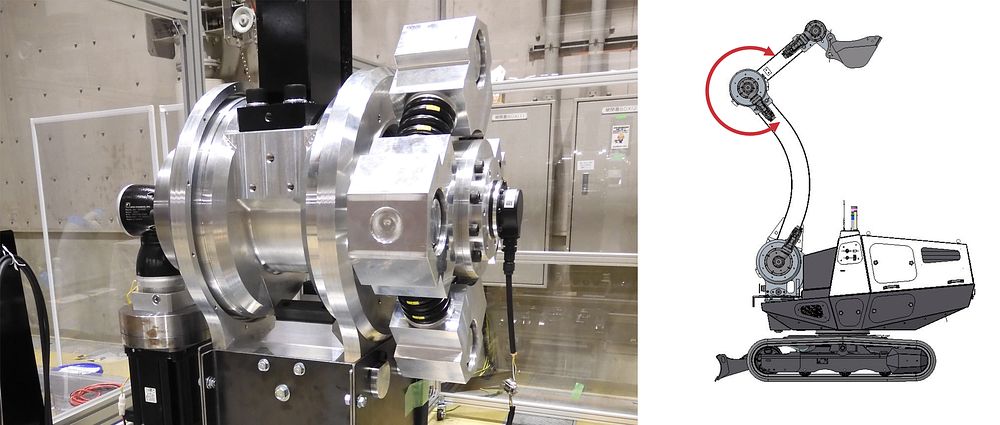

Developed in collaboration with JAXA's Space Exploration Innovation Hub Center※1, the large SEA (Series Elastic Actuator), was part of a prototype for the next-generation work machine under the Moonshot Research and Development Program※2. Yanmar HD successfully implemented force control capabilities, a challenge for conventional hydraulic systems. Using the SEA composed of an electric motor, reducer, and spring, the functionality was implemented in an electric mini-excavator.

This technology aims to automate fine manual tasks, addressing labor shortages at construction sites. Moving forward, the company plans to conduct further verification to realize the practical applications of next-generation work machines in construction sites and similar environments.

Aligned with the company’s YANMAR GREEN CHALLENGE 2050, the Yanmar Group continues its commitment to realizing a sustainable society, contributing to customers' decarbonization efforts through ongoing developments in electrification and other forward-looking technologies.

Key Features:

- Test development of force control function using a large SEA that can be mounted on construction machinery.

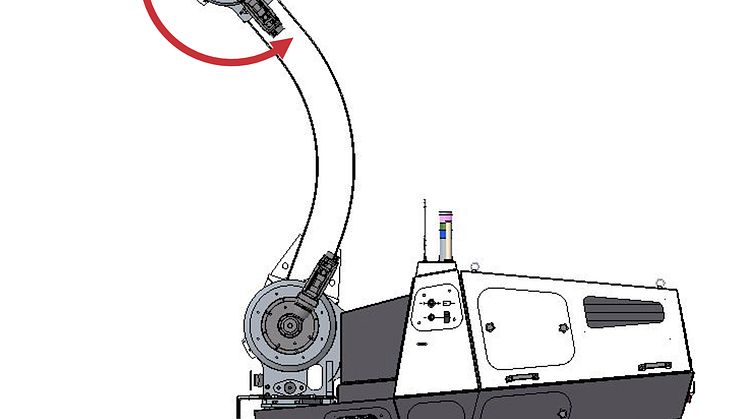

- Development of a prototype incorporating this technology into a mini-excavator as part of the Moonshot Research and Development Program.

- Mechanization of delicate work in civil and construction sites, contributing to the labor-saving of material placement operations.

- Implementation of an articulated motor, not a conventional electric cylinder, to expand the range of motion through electrification, enabling high-altitude work like ceiling operations.

Main Specifications (prototype)

| Name | Next-generation work machine prototype with force control function |

| Base machine | Yanmar ViO25 mini-excavator |

| Weight | 3t class |

| Rated load during lifting | 209kg |

| Operating range | 210 deg. |

| Emissions | Zero-emission |

About Moonshot Research and Development System (Japanese govt. cabinet office)

https://www8.cao.go.jp/cstp/english/moonshot/top.html

Ref.: Joint Research Results Verification Experiment on Control Technology of Construction Machinery for Moon Base Construction (Japan Aerospace Exploration Agency, Space Exploration Innovation Hub Center, September 21, 2023)

(Japanese)

https://www.ihub-tansa.jaxa.jp/topics/yanmar.html

※1: Space Exploration Innovation Hub Center: Research and development of construction machinery with force control functions under the challenge name "Research and Development of Construction Machinery with Force Control Functions."

※2: Moonshot Research and Development Program Goal 3 "Collaborative AI robots for adaptation of diverse environments and innovation of infrastructure construction": Research and development of collaborative AI robots capable of flexible response to unforeseen situations and performing tasks in difficult environments, such as disaster sites or the moon.

Related links

Topics

Categories

Note: Information contained in the news release is valid at the time of publication and may differ from the most recently available information.

[Inquiries for further information]

Corporate Communications, Yanmar