News -

BASF Starts Up 54-Megawatt Water Electrolyzer

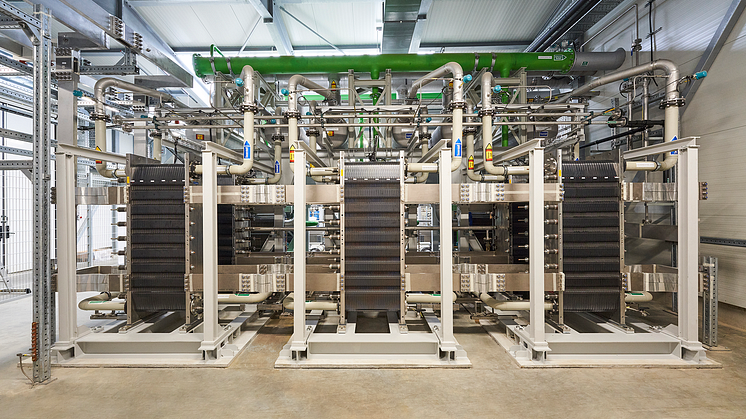

Germany's largest proton exchange membrane electrolyzer (PEM) has been put into operation at the BASF site in Ludwigshafen. The 54-megawatt plant produces CO₂-free hydrogen at a rate of up to one metric ton per hour. After a construction period of around two years, the electrolyzer was inaugurated in the presence of Minister Katrin Eder and State Secretary Udo Philipp.

The electrolyzer, which was built in collaboration with Siemens Energy, is the first of its kind in the world to be integrated directly into the chemical production infrastructure. The 72 stacks in which the electrolysis process takes place enable a reduction of greenhouse gas emissions by up to 72,000 tons per year. The hydrogen will be fed into the H2 network and used as a raw material for chemical production. In addition, the hydrogen is intended for mobility in the Rhine-Neckar metropolitan region to promote the regional hydrogen economy.

The Hy4Chem project received up to 124.3 million euros in funding from the German Federal Ministry for Economic Affairs and Climate Protection and the state of Rhineland-Palatinate, including 37.3 million euros from the state. BASF invested around 25 million euros in the project, which was funded as part of the IPCEI hydrogen initiative.

Katja Scharpwinkel, member of the BASF board, emphasized that the commissioning of the electrolyzer makes it possible to support customers with products that have a lower carbon footprint. Alexander Schweitzer, Prime Minister of Rhineland-Palatinate, called the project an important milestone for the hydrogen economy and the decarbonization of the chemical industry. Udo Philipp of the German government emphasized that the project serves as a pioneer for the decarbonization of industry and the achievement of climate targets.

Katrin Eder, Minister for Climate Protection, emphasized the importance of the project for the climate targets and greenhouse gas neutrality of Rhineland-Palatinate. The new electrolyzer plays a central role in the conversion of hydrogen production from natural gas-based steam reforming to green hydrogen production.