30% reduced CO2 emissions in quay work for the Skandia Gateway project

Climate-smart quay construction in Skandia Gateway: 30% lower CO₂ emissions at only 1% higher cost, thanks to material requirements and innovation.

Climate-smart quay construction in Skandia Gateway: 30% lower CO₂ emissions at only 1% higher cost, thanks to material requirements and innovation.

During the second quarter of 2022 the service ship Northern Skagerrak will be converted to hybrid operation. It will run mostly using electric power although there will also be an auxiliary engine that runs on the renewable fuel HVO.

The Skandia Gateway project is already under way and construction is scheduled to begin during the first quarter of next year 2022. The fairway needs to be deepened to 17.5 metres if the world’s largest ocean-going vessels are to be able to call at the Port of Gothenburg fully loaded. This will prove crucial if Swedish industry is to have greater access to the world in the future.

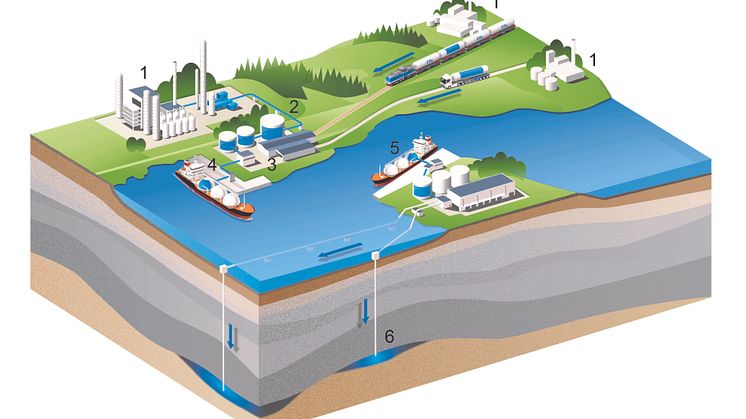

Gothenburg and Sweden could be the first in the world to create a joint infrastructure for the transport of liquefied carbon dioxide extracted using CCS technology. The project – CinfraCap – is a unique collaborative venture between Göteborg Energi, Nordion Energi, Preem, St1, Renova, and Gothenburg Port Authority.

Last year, one in three ships at the Port of Gothenburg received an environmental discount on the port charges. This represents an increase of 83 per cent on the previous year. Heading the discount list are Donsö-based shipping companies Tärntank Ship Management AB and Furetank AB, whose vessels are powered by liquefied natural gas.

Measurements at the Port of Gothenburg show that sulphur emissions from ships have fallen by 80 per cent since stricter rules came into force at the turn of the year.

The Port of Gothenburg's campaign for a cleaner shipping industry is continuing to bear fruit. During 2013, 49 vessels took part in the programme. In total, they saved 120 tonnes of sulphur emissions.