Why Don’t I Input a Coupling Diameter?

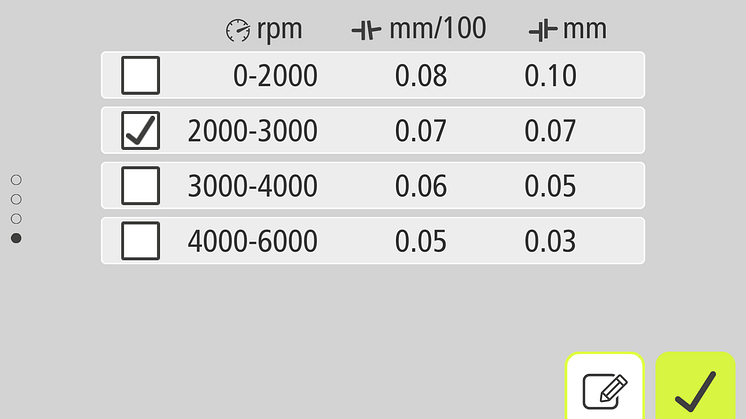

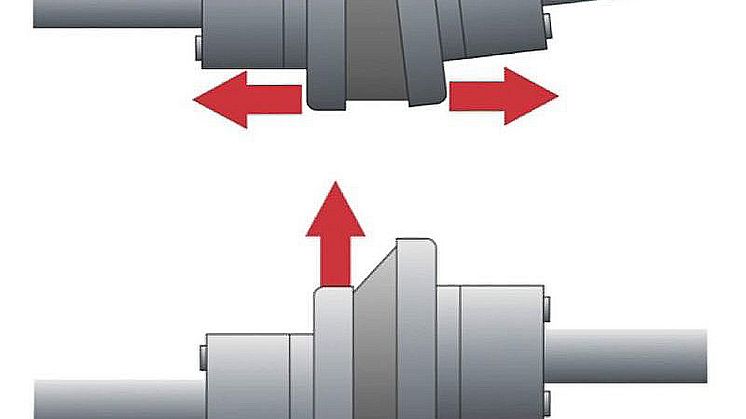

Tolerances for shaft alignment are typically expressed in terms of angle and offset. It is common knowledge that offsets cause confusion, but angularity often confuses those tasked with aligning or verifying alignments.