Dial Indicator Alignment – Bar Sag Still Exists in 2018!

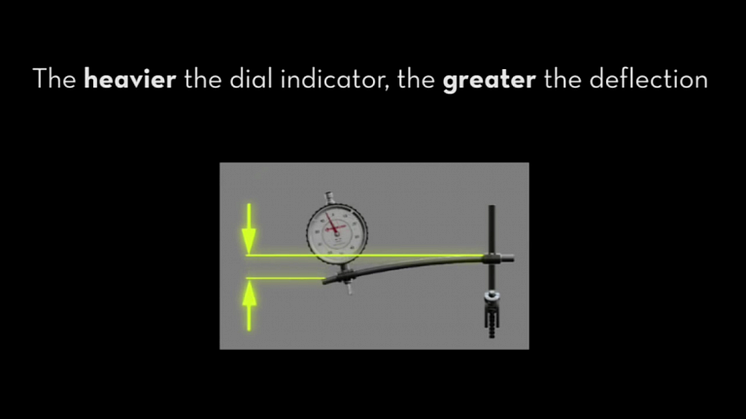

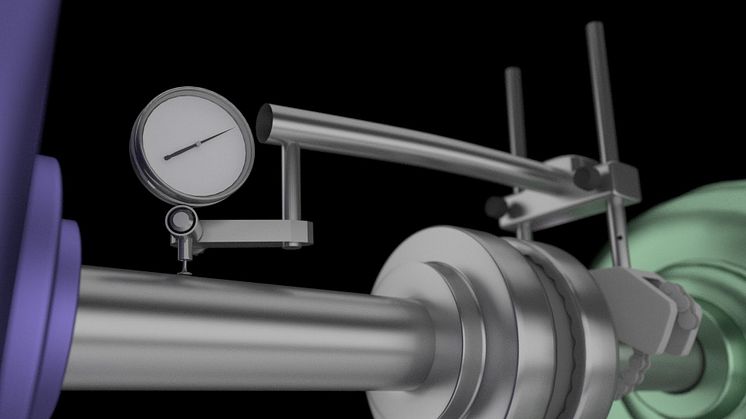

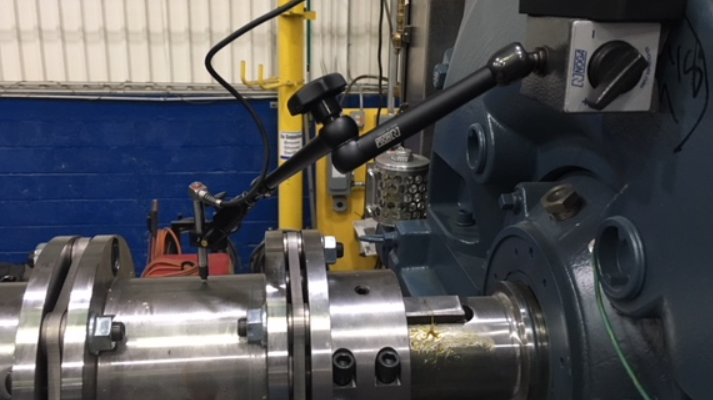

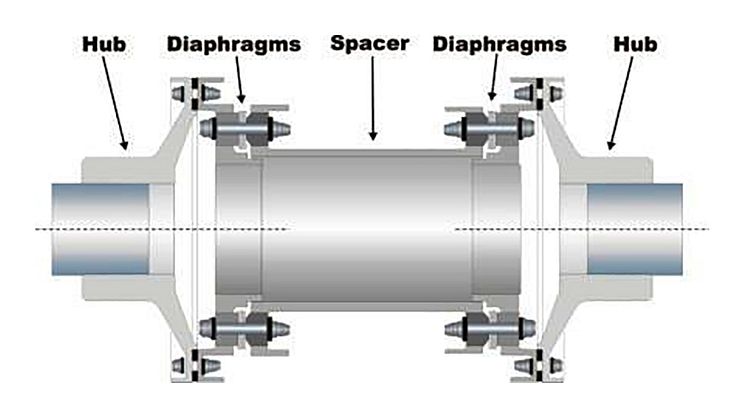

Dial indicator bar sag describes a bending of the hardware used to support a dial indicator or other part which spans the coupling. The bending action occurs as a result of gravity and cannot be totally eliminated in almost all cases of alignment.