The Maintenance Supervisors 5 Questions

These are the five questions every maintenance supervisor needs to answer.

These are the five questions every maintenance supervisor needs to answer.

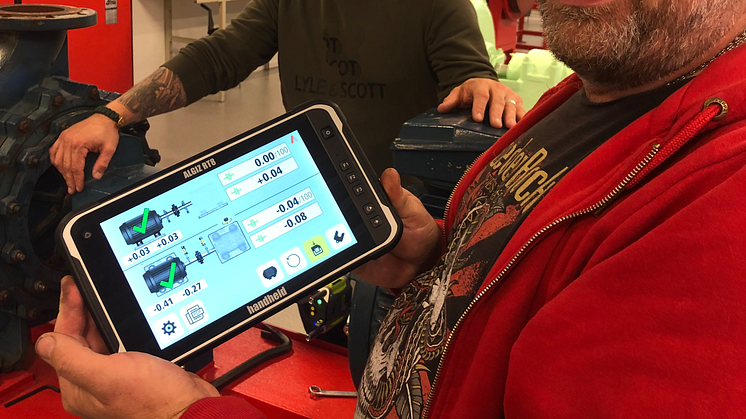

The adaptive user interface will guide you throughout the measurement and alignment process. We are especially proud of the function – VertiZontal Moves™ – where you only have to measure once before making the required vertical and horizontal adjustments. Quite a time conserver in a time strained maintenance world!

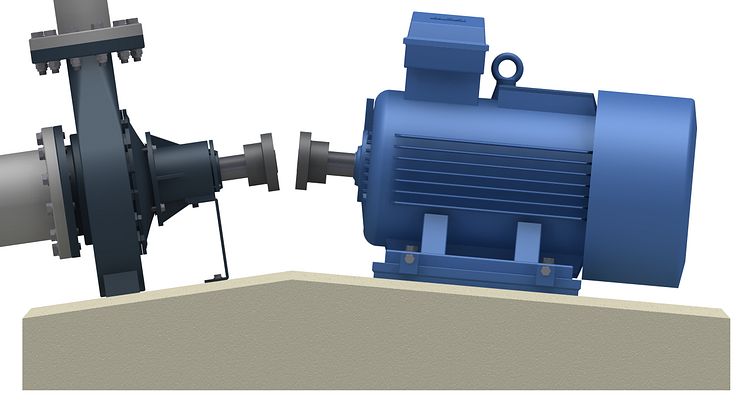

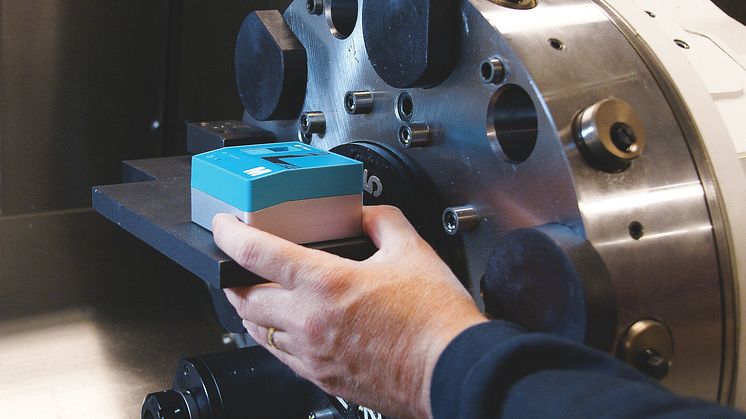

There were huge differences between coupling alignment tolerances and precision shaft alignment tolerances during a recent Acoem RT-300 training class. Electric motors and centrifugal pumps fitted with grid couplings of model 1070T were aligned at 1800 RPM. A contractor performed the initial alignment on this fairly new installation.

Verifying your machines' issues using phase analysis can be a very effective method of verifying faults discovered during an inspection. Vibration programs can be made more effective when phase, particularly cross-channel phase analysis, is applied properly.

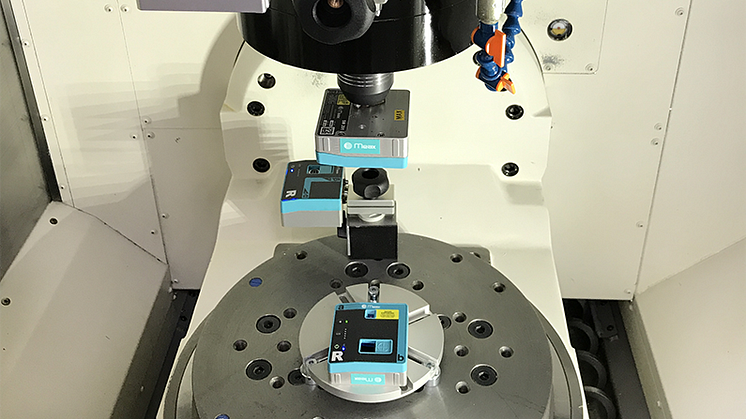

The machine tool industry has been around for a long time and it is exciting to see how the industry continues to thrive and incorporate new technology and processes. What do you think the future might hold for this industry?

The machine tool world can be overwhelming if you are new to it. You may hear terms like tolerances, CNC, CPK, surface finish, uptime, and cost per part thrown around, and it may seem like a foreign language if you are just starting out in this industry.

CNC machine leveling is an essential function. Optimizing a machine's capability and producing high-quality parts is a key element of its capability.

There are many tools on the market to use in conjunction with lubrication – mechanic’s stethoscopes, “smart” grease guns which use ultrasonic, or just an ultrasonic tool itself. High-frequency vibration measurements can also do this.

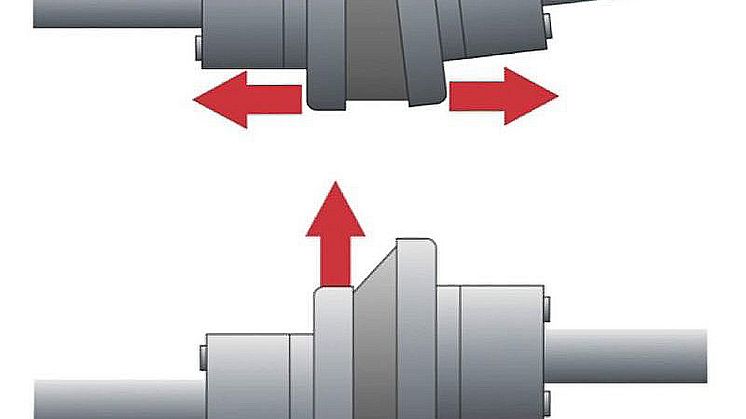

When using a straightedge to perform a shaft alignment you won’t see angular misalignment.

ACOEM AT-100 NEW entry-level smartphone and tablet-based alignment tool that utilises the latest sensor technology and the renowned Acoem user interface, GuideU™

To calculate the cost of misalignment, first determine the cost of the machine’s downtime.

We have several times discussed the differences between coupling alignment tolerances and precision shaft alignment tolerances. As stated in those text the coupling manufacture’s tolerances are for the coupling. As maintenance professionals we are concerned with the coupling, however we are more concerned with the bearings in the machines.

Belt Drive advantages - quiet in operation, require no lubrication, and are relatively cheap to produce.

The NXA Runout Probe is a simple electronic tool designed to detect and measure shaft runout. The new tool represents a unique application of a linear variable displacement transducer (LVDT) to provide an easy-to-use but highly accurate measure of machinery problems that can confound the measurement and correction of shaft misalignment

When everything is running smoothly, digging for the necessary protocols or procedures may feel cumbersome, but doesn’t necessarily set off bells and whistles that a bigger problem may be lurking.

Predictive maintenance involves scheduled testing on regular intervals.

A key thing to understand when it comes to belts is proper sizing. Whether you are using a correctly-sized belt for your machine will have a significant impact on the machine’s ability to function at an optimal level.

We’ve identified 6 common machine faults you’ll likely encounter on your maintenance routes.

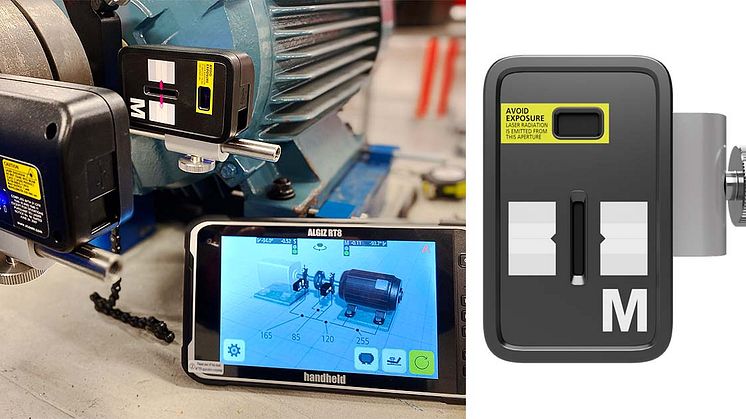

During a recent class in a shipyard, there was a need to perform a Cardan Shaft Alignment in a boat with very little space to work in. It also required shooting the lasers through a hole in a bulkhead.

Looking from the S sensor through the bulkhead at the M Sensor mounted on engine output shaft

S Sensor mounted on propulsion unit

It was a challenge, but the guys rose to it and the result

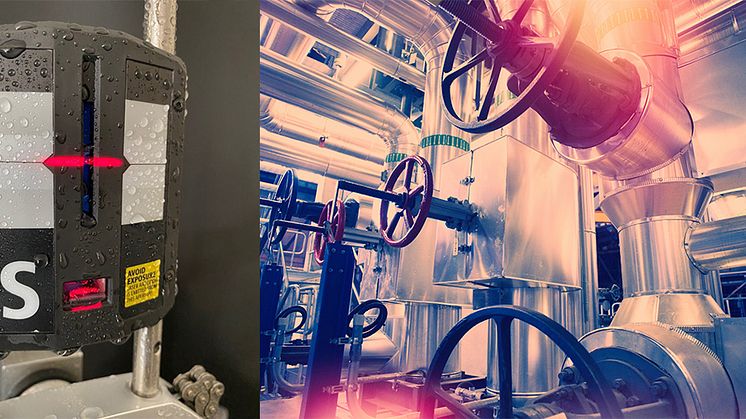

Can the laser alignment tool withstand use in wet conditions? How resistant is the laser alignment tool to moisture? Sometimes these questions are asked in the context of making a purchase decision to go with one model over another. Other times the questions are driven by some difficulty in completing an alignment in a high moisture environment.