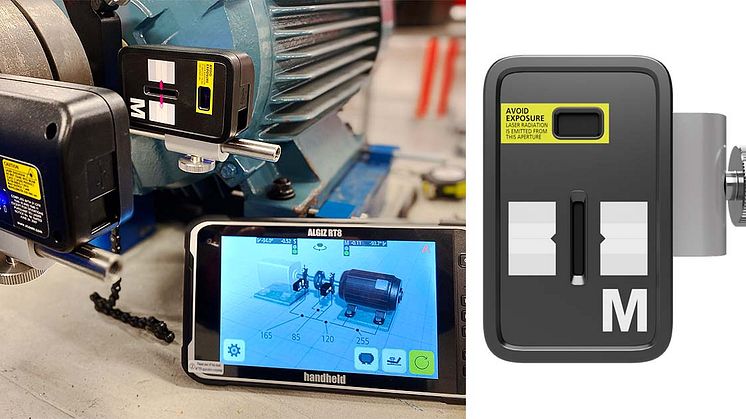

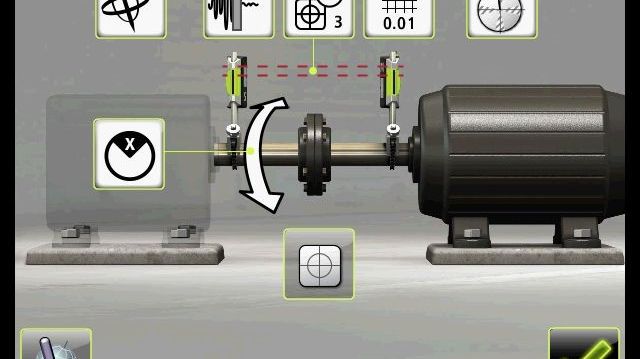

ACOEM AT-serien, fem verktyg med varierande skicklighet och styrka för att säkerställa optimal axeluppriktning!

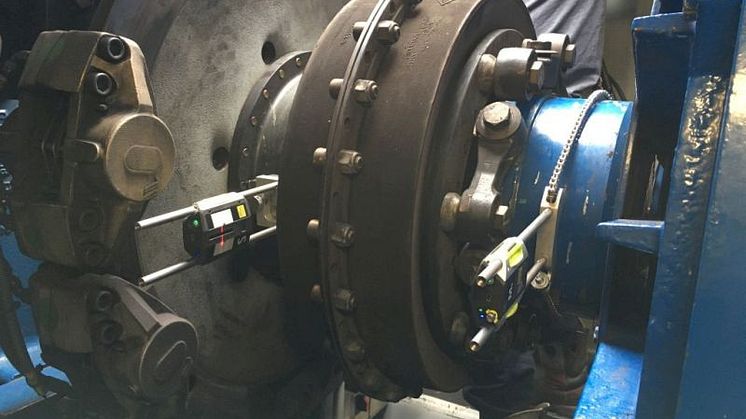

Acoem erbjuder AT-serien för laseraxeluppriktning. AT-100 är grundläggande, passar för pumpar och små fläktar. AT-200 är för industriella pumpar och större fläktar. AT-300 har avancerad precision för olika maskiner. AT-400 är flaggskeppet med innovativa sensorer för exakt uppriktning. EXO är specialiserad för explosiva miljöer. Valet beror på maskintyp och budget.