Press release -

Cutting, welding, milling and drilling with new high-precision FANUC robot

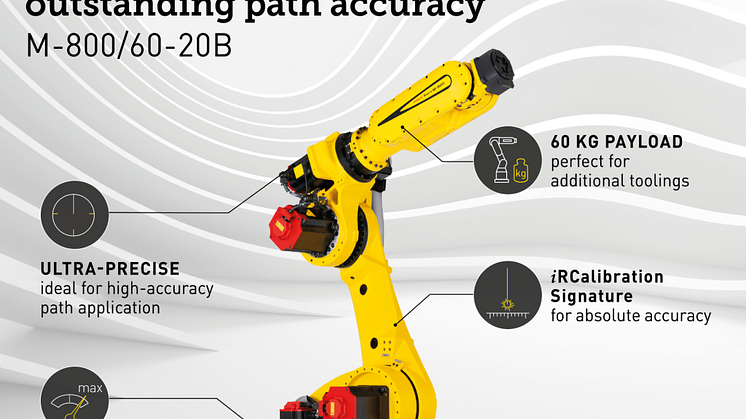

FANUC’s new, second-generation M-800/60-20B is a high-accuracy robot with 60 kg payload capacity that offers outstanding performance in high-precision applications. The robot delivers path accuracy of ±0.1 mm thanks to enhanced rigidity, advanced process supervision with FANUC’s new R-50iA robot controller, and the inclusion of the company’s Accuracy and Stiffness Enhancement option.

The M-800/60-20B high-precision robot offers superior mechanical design rigidity compared with conventional robots in the same class - while maintaining the same high levels of productivity. In combination with FANUC’s new R-50iA robot controller users benefit from better robot accuracy. In addition, improved accuracy of I/O trigger timing and sensor tracking on the robot’s motion path further support precision in any sensor-following applications that require exceptional path control.

“With our new M-800/60-20B, manufacturers can use a high-precision robot to undertake processes such as 3D laser cutting and welding, as well as waterjet cutting, plasma cutting, milling, boring and drilling in a wide range of engineering materials,” explains Paul Ribus, FANUC’s Head of Robot Sales Coordination Europe. “This offers a cost effective alternative or complement to traditional CNC machine tools, enabling users to benefit from the robot’s best-in-class circular and linear path accuracy of ±0.1 mm, ±0.015 mm repeatability, six degrees of freedom, and 2040 mm reach.”

Among the major manufacturing trends set to benefit is giga casting, a manufacturing process that creates large, single-piece castings such as car body structures, typically using high-pressure aluminum die-casting machines. Here, the subsequent milling, boring and drilling of giga castings requires the use of enormous machine tools. However, the path accuracy of traditional robots is often insufficient to perform this task. The new M-800/60-20B is now among a selection of FANUC robots that present a far more cost-effective alternative to CNC machines in applications such as the machining of giga castings and other die-cast components.

FANUC’s Accuracy and Stiffness Enhancement option serves to minimize the effects of gear and reducer backlash, leading to smoother and more accurate movement. It includes iRCalibration Signature, FANUC’s precision calibration technology that provides higher absolute position accuracy by compensating for any manufacturing deviations from design values and mechanical torsion due to gravity (when the robot arm is extended in horizontal position). The Accuracy and Stiffness Enhancement option also compensates for deflection due to lateral forces in processes such as milling.

Among further improvements is dust and water resistance, again important for processes like the laser cutting/welding of aluminum or aluminum-plated materials, ensuring the robot can be deployed with confidence even in environments where airborne contaminants are present. The M-800/60-20B carries IP67 protection rating for its wrist and upper arm, and IP54 for the body. FANUC can also offer a proprietary remote laser head that works in combination with the robot to perform efficient welding or cutting on the fly.

Enhancing user comfort is FANUC’s new Lightweight Teach Pendant with full touch-panel operation. Believed to be the lightest in its class at just 750 g, the new Teach Pendant improves user experience by making programming both faster and easier.

Related links

Topics

Categories

Regions

The FANUC Corporation is the world leading provider of factory automation. FANUC’s extensive portfolio of products for industrial automation includes CNCs, industrial robots, vertical machining centers, injection-molding machines, wire cut EDM machines, drives and laser technology (ROBODRILL, ROBOCUT and ROBOSHOT).

Since 1956, FANUC is the pioneer in the development of numerically controlled machines in the automation industry. With more than 260 FANUC locations worldwide and more than 9,000 employees, FANUC offers a dense network in sales, technical support, research & development, logistics and customer service.

FANUC Nordic is a subsidiary to FANUC Europe and provide sales and service to all Nordic and Baltic customers. FANUC Nordic has 60 employees with Head office and Experience Center in Malmö (Sweden). FANUC Nordic also has branch offices in Vantaa (Finland), Odense (Denmark) and Sollentuna (Sweden).