Pressmeddelande -

3D surfaces can notably improve window energy performance, while reducing material use and environmental impact.

In a project sponsored by the Swedish Energy Agency, Reliefed Technologies has achieved a critical milestone; showing that the thermal insulation capacity (Uw-value) of a window profile can be improved with the help of 3D optimization, enabled by the manufacturing technology z.trusion®. If applied on the full window system in an entire commercial building, 3D optimization has the potential to significantly improve the building energy consumption, meeting the tougher and tougher building energy requirements, while ensuring daylight and reducing material use.

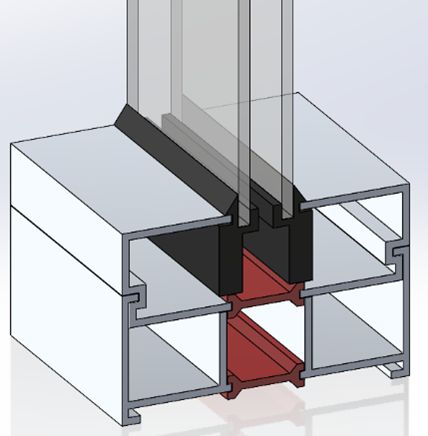

Most people don’t know this, but aluminum framed windows contain multiple insulating elements called “thermal break profiles”, with the main purpose to keep the heat or cold from the outside of the building to reach the inside of the building. The insulating ability (Uw-value) of these seemingly insignificant window elements will effect the insulating performance of the entire window. In new and well isolated buildings, with a large percentage of the façades covered in glass sections, the performance of the windows can play a critical part in the energy consumption of the full building. That’s why windows with an overall good insulating performance typically receives governmental grants when being installed.

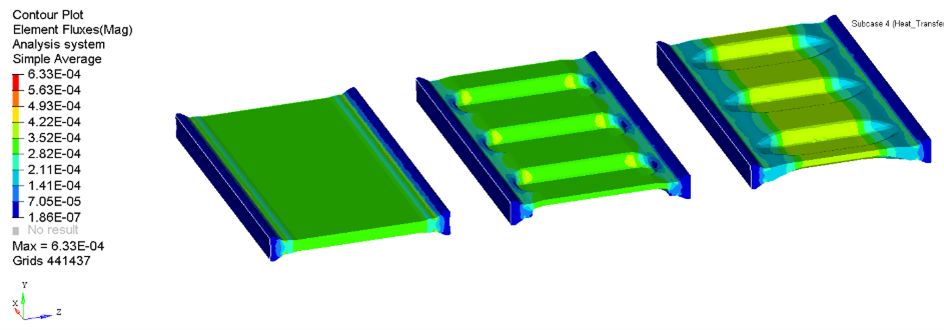

z.trusion® is a patented manufacturing technology that enables the mass-production of profiles with varying cross section (3D surfaces), in one single, cost effective manufacturing step. To investigate what this technology can bring to the construction industry, Reliefed Technologies teamed up with Swedish Energy Agency to perform an initial study on how much the insulation capacity of a standard thermal break profile can be improved by adding the 3D topologies enabled by z.trusion®. The hypothesis being that the longer the heat must travel, the better the insulation capacity.

The initial result of the project, with thermal simulations performed by independent analysts, shows that the 3D optimization of a standard thermal break profile can mean a 35% improved thermal insulation in the profile, while maintaining the same physical properties. The final report, issued by RISE, shows that this optimization can affect the thermal transmittance (Uw-value) of the full window frame by 7% and the complete, standard window with between 3-4% (Read the report here).

The 3-4% improved thermal insulation of the window might not sound as much, but bear in mind this is only an initial optimization of one standard profile. Imagine if this technology was put in the hands of the window manufacturers and their experts, who can properly optimize the full window- and façade system. The results could not only be significantly improved insulation capacity with reduced energy consumption of buildings, but it also be a great business opportunity, as more window designs would be certified, and production cost will be decreased. – Says Mikael Eklund CEO of Reliefed Technologies.

An additional result from the optimization of the thermal bridge profile is that 20% of material (PA66) can be saved, reducing cost in production but also reducing the environmental impact of the product, which will be visible in the product’s EPD value. As of this year, the construction industry are required by law to declare the environmental impact in a building’s construction phase (Boverket), making material reduction an even more important priority in the industry.

Already at manufacturing of one standard thermal profile, we can show the potential to save approximately 100gram PA66 per m2 window, thanks to topology optimization and z.trusion®. This equals to a cost saving potential at ~€0,67 per m2 window and ~0,6-0,9 kg CO2e reductions per m2 window at the same time. To sum up, with our topology optimized profiles you can save money and reduce emissions, all at the same time, from day on –says Mark J Kragh, Chief Innovation Officer at Reliefed Technologies.

Recently, the requirements for new apartment buildings in Sweden was sharpened to ensure new buildings have a thermal transmittance value that doesn’t exceed 0,4 W/m2 K (Boverket). This in turn sets the requirement for the windows installed in the building, where the balance between daylight and energy requirements is getting harder and harder to reach. Also in Europe there is a trend towards tougher environmental requirements in the sector, as can be seen with the new EU-taxonomy (European Comission).

The overall expectation is that the environmental requirements on buildings in Sweden will be sharpened even more going forward. This means that every improvement in improved insulation can be of importance. For example, 1,1 vs 1,2 Uw-value (thermal transmittance) on a window is a huge difference for a window manufacturer, since it will determine if it classifies as energy product and thereby receives additional grants for the installation. - Says Eva-Lotta Kurkinen, Tekn.dr. Klimatskal & Byggnadsfysik at RISE Research Institutes of Sweden.

Relaterade länkar

Ämnen

- Bygg, fastighet

Kategorier

- byggindustrin

- thermal optimization

- partnerskap

- plast

- 3d-produktion

Regioner

- Skåne

z.trusion® is a patented technology for innovative and sustainable design of extruded products, developed by award-winning Swedish cleantech company Reliefed Technologies. The company is headquartered in Varberg on the Swedish west coast and collaborates with industry leaders across Europe.