Blog post -

FOUR REASONS TO TEST THE DUST PRODUCED IN YOUR FACILITY

Dust testing is important regardless of how long you’ve been producing the same type of dust or the age of your dust collection system. You may think that you have an understanding of the type of dust produced during your operations, but changes in equipment, regulations or products can mean that it’s time to have your facility’s dust evaluated. Dust testing is easy and can help you save money on filters and energy. It can also help you maintain compliance and keep your employees safe. Here are four ways that testing your dust can benefit your facility and your personnel.

1. PROTECT YOUR PERSONNEL

We’ve said it many times. Dust can be harmful or downright dangerous if not contained properly. Dusts can be explosive or cause health issues, so having a strong knowledge of all the dusts in your facility and their characteristics is critical to keeping your employees and property safe.

The best way to know how to properly contain your dust is to have the dust tested. The burden of proof is on manufacturers to demonstrate that their dust is not combustible, so it is important to have process dust tested by a valid third-party testing lab and to keep records on file proving that it is not combustible. If your dust is determined to be combustible, consult with an expert about adding explosion protection to your dust collection system to mitigate an explosion.

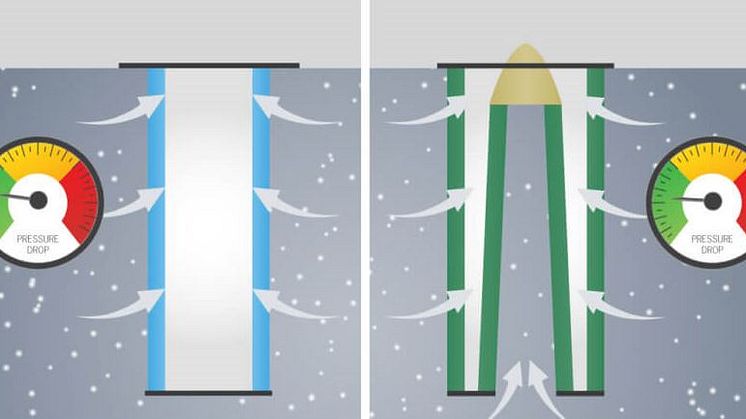

2. SELECTING THE RIGHT FILTER

Just as all dust is not created equal, neither are dust collector filters. There are many different types of dust and each has its own unique characteristics. Dust collector filters are made to effectively trap and mitigate dust particles based on their characteristics. Some dusts, like Crystalline silica or hexavalent chromium, are hazardous to human health and require high-efficiency filters that meet OSHA requirements. Others, like those generated from food processing applications, may be moist or sticky and would benefit from washable polyester filter media. For dust containing oils, filters with an oleophobic coating will be necessary. And the NFPA recommends grounded cartridges for metal containing mixtures.

By having your dust analyzed, you can learn exactly what type of filters you should be using in your dust collector. This will help your dust collector perform better and use less energy, and your filters will last longer and pulse clean more efficiently and protect workers by greatly reducing the respirable dust.

3. IMPROVE DUST COLLECTOR PERFORMANCE

If your dust collector is working overtime to clear the air, it may not be set up optimally for the type of dust it’s collecting. Is your dust collector gorging itself on compressed air? It may not be pulse cleaning effectively enough to maintain a steady airflow. As stated above, dust testing helps determine the proper filter to effectively release dust during pulse cleaning.

The way your dust moves will also determine the best setup for your dust collection system. Based on industrial ventilation guidelines and a dust characteristics analysis, our dust experts can determine the correct filter housing size, ductwork system design and hopper/dust discharge design for your specific dust. With a proper setup, your dust collection system will use less energy, consume less compressed air and collect dust more efficiently.

4. MAINTAIN COMPLIANCE

Some dusts are dangerous to human health or are combustible or explosive. Having a strong, thorough knowledge of your dusts and their characteristics is key to maintaining the necessary compliance.

There are four major federal organizations who create and maintain safety standards, three of which can regulate and enforce rules to help maintain the necessary compliance:

- Occupational Safety and Health Administration (OSHA): OSHA governs workplace safety. Their General Duties Clause mandates that employers offer their employees a safe workplace free from hazards. They also regulate permissible exposure limits (PELs) for many types of hazardous contaminants like dust and fumes.

- National Fire Protection Association (NFPA): The NFPA is a national organization dedicated to preventing death and property damage from fire, electrical and related hazards. NFPA 652 compliance requires that all facilities that generate, handle or store potentially explosive dust have it tested for combustibility. This means companies need to prove their dust isn’t combustible and have the paperwork to verify it.

- Environmental Protection Agency (EPA): The U.S. EPA protects the environment and therefore regulates exhaust systems that vent outdoors. One example of an EPA regulation that affects dust and fume collection is National Emission Standards for Hazardous Air Pollutants (NESHAP) Rule 6X. This rule primarily affects welding and metal working operations and requires that facilities using these practices perform a Method 22 Fugitive Emissions Test. This test requires that emissions are monitored and action be taken to contain the emissions should they fail the test.

- Food and Drug Administration (FDA): The U.S. Food and Drug Administration puts mandates on dusts produced by both food and pharmaceutical manufacturing facilities. Some food dusts like flour can be explosive if not properly contained, and other regulations like the Food Safety Modernization Act require that measures be taken to prevent food cross-contamination, particularly involving allergens. Pharmaceutical manufacturers also have to abide by regulations that prevent cross-contamination and employee exposure.

HOW WE ANALYZE YOUR DUST

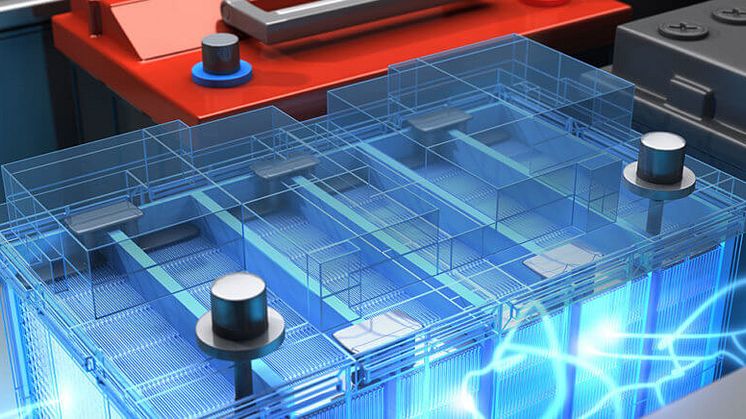

Dust analysis only requires a dust sample from you. From there, our team of experts uses various tests and testing equipment to analyze the characteristics of your dust to determine the right setup for your dust collection system. However, any combustible dust testing should be performed by an accredited lab with the proper equipment per NFPA requirements.

PARTICLE SIZE ANALYSIS

This analyzes the dust particle size down to the submicron range, which helps to determine the efficiency required to meet emission standards. We use a dual-laser particle analyzer to determine the distribution of particles across a range of sizes and the volume or mass spread of the dust. It is important to know both because many dusts are mixed in the air prior to collection.

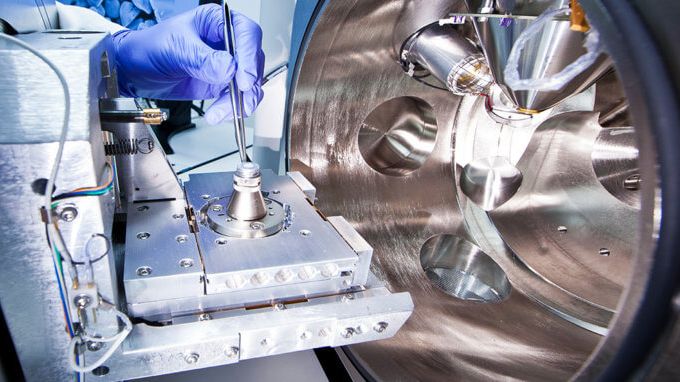

VIDEO MICROSCOPES

An optical microscope and a scanning electron microscope (SEM) can be used to visually determine dust shape and characteristics. The optical microscope is used to observer the shape of the particles and the SEM provides elemental analysis and detailed media images. The data is combined with the particle size analysis to help determine what type of dust collector and filters are best for collecting this type of dust.

ABRASION TESTING

Abrasion testing helps determine the optimal design of dust-handling components based on how abrasive the dust is. This includes the design of inlets, baffles, discharges, and ductwork. It is important because when capturing a highly abrasive dust, like cast iron grindings, the collector must be designed with low inlet velocity. If the inlet velocity is too high, the dust will abrade the filters and cause premature wear.

OTHER TESTING

Moisture testing is also a very important part of dust testing because excessive moisture can lead to poor filter life. If you are dealing with moist dusts, early detection is important to select the proper type of filter media. We use a hygrometer to identify the presence of moisture in the dust. If necessary, we then dry the sample to determine the moisture by weight as a percentage. We also test to determine equipment designs like hopper angle and conveying velocities.

When you’re ready to have your facility’s dust analyzed, our experts are here to help. Our state-of-the-art dust collection test facility can provide the data you need to avoid guesswork, invest wisely in equipment and keep your team safe. Click here to learn more.