News -

Green – the new color of business

Yanmar has been on its zero greenhouse gas emissions path for over a decade. The scale of the challenge is huge – and success will be driven by economic considerations more than concern for the climate, believes Chief Strategy Officer Shiori Nagata.

Japan is an island with limited natural resources. We hate waste and have learnt the merits of circulating everything. Making better use of resources goes right back to 1912, when our founder Magokichi Yamaoka set up Yanmar with the aim of making more efficient use of fuel in engines. Then the ‘fuel’ was just oil, but today the options are so much wider – bringing hope for a cleaner future – but complexity at the same time.

At the Yanmar Group our Brand Statement since 2012 has been ‘A Sustainable Future’. This is not just to please our ESG investors, it is truly our passion, our purpose – and our dream.

…but no one said it was going to be easy

Even now that we are a decade into our ‘Green Challenge’ we still forecast that it will take a further 28 years to achieve our zero environmental impact goal. By 2050 we will be totally free of greenhouse gas emissions in our business activities, circulate all resources and support our customers so that they can achieve the same greenhouse goals as us.

Of course, we would like to achieve our climate/societal goals faster, but we must be realistic as to the scale of the challenge. In 2019 we calculated that we caused 0.2 million tons of CO2 to enter the atmosphere from what we define as our scope 1 & 2, while a further two million tons came from our supply chain – and a staggering 80 million tons of CO2 was released from customers using our machines.

Changing this is going to take time. Our machines are made from steel, plastics, rubber etc. – and many of these components currently have no (or limited) green options. But we are committed to using them as they become available. In the meantime, we will source green energy and create our own, using solar panels on factory roofs. It will be a step-by-step approach, and different countries and customers will move at different speeds. This is much more than a Yanmar challenge – going green is as much a societal challenge as a technical one.

Electric machines make business sense

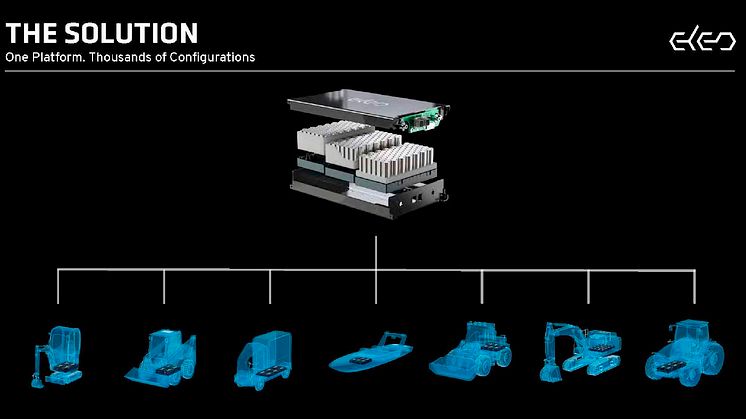

Electrifying our machines will be vital in achieving our zero carbon ambitions. And it is going to happen. But this is not as simple as in the car business, and many hurdles to adoption remain. The charging infrastructure needs to develop, and battery machines need to be proven in the harsh work environments of construction. People won’t buy electric machines to save the planet – they will buy them because they make economic sense. Fortunately, as costs fall, the total cost of benefit of using electric machines will make them the compelling option. As with the new range of electric machines we launch at bauma, they are simpler, more comfortable, with low vibrations and noise, and lower running costs.

We are starting on the energy transition with battery electric powered smaller machines, but by the end of the decade we will introduce hydrogen power in our larger equipment. All the major components of electrification are on a sharp development curve that will continually make them better. It’s a step-by-step approach to the green future we seek.

Multi-fuel future

Even electric machines have their own environmental challenges – if the electricity that powers them comes from a lignite coal power station, is it really that cleaner? Perhaps controversially, the much-maligned internal combustion engine (ICE) has a part to play in the green future. It must – if we all went electric today there isn’t nearly sufficient electricity generation to power all our equipment. But the ICE can be made clean, by burning non-CO2 fuels such as hydrogen and other much cleaner biofuels. Even here there are difficult choices to make – biofuels compete with food production, and in a world of growing hunger, what takes priority – the climate tomorrow or survival today? That too is society’s challenge to answer. What is clear is that we will go from a single fuel type – diesel – to diversified fuel types in the future. If it’s a choice of extra complexity to make the environment better, then it’s a challenge we are happy to accept!

At Yanmar we take global food scarcity seriously. We are applying our ‘no waste’ philosophy to supporting farmers with precision agricultural solutions. We have developed a recycling machine that takes waste food, dries and processes it by microbial action, and produces a nutrient rich fertilizer. The perfect example of resource circulation.

Meeting society’s challenges

So, meeting the goals of our Green Challenge will take until 2050 to achieve. There is no short cut. We are optimistic about a carbon free future – but also realistic about what is possible – and how fast it can become a reality.

These ideas come from a heartfelt passion to build something good for society and the environment. Our purpose is to meet society’s challenges with intelligent solutions. We’re committed to green being the new color of business.