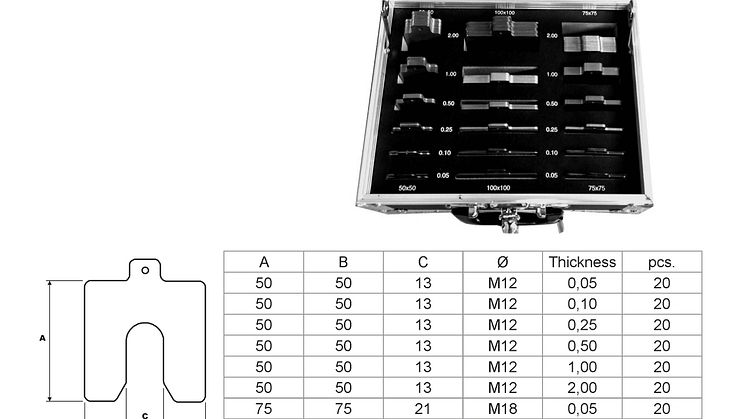

Kontrollera dina shims före uppriktning! 👍

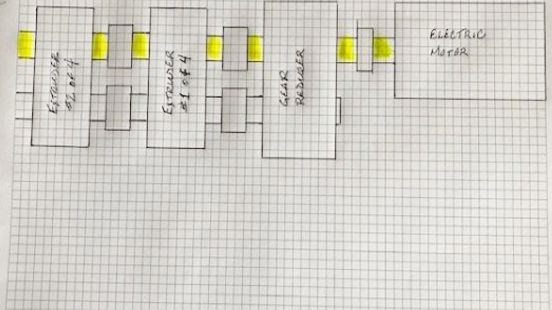

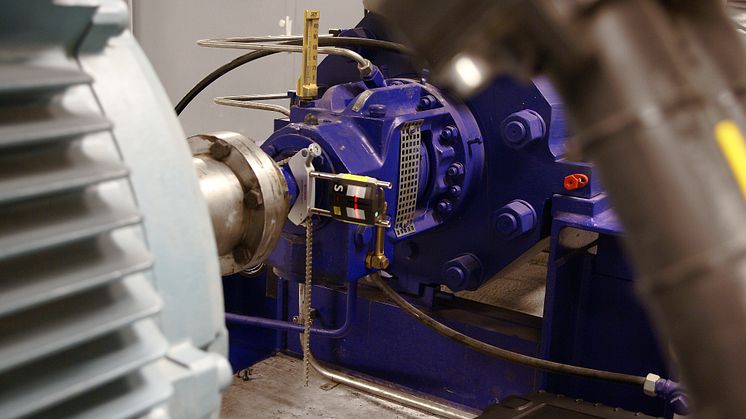

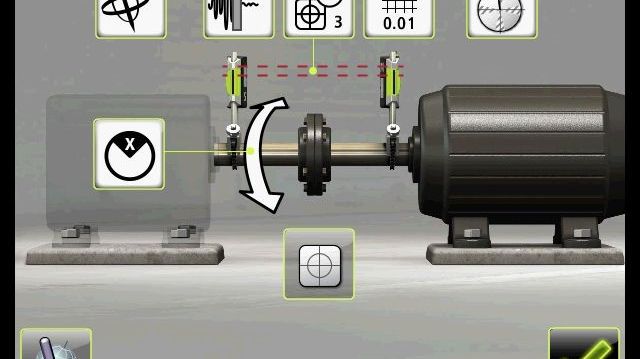

Har du någonsin lagt till antalet shims som ditt uppriktningsverktyg säger att du ska göra bara för att upptäcka att din maskin fortfarande inte är korrekt? Detta är en frustrerande men vanlig förekomst. Var det ett beräkningsfel eller gav ditt axeluppriktningsverktyg dig fel information? Mer än troligt är dina shims är skyldiga.