News -

What is Nonwoven? Really!

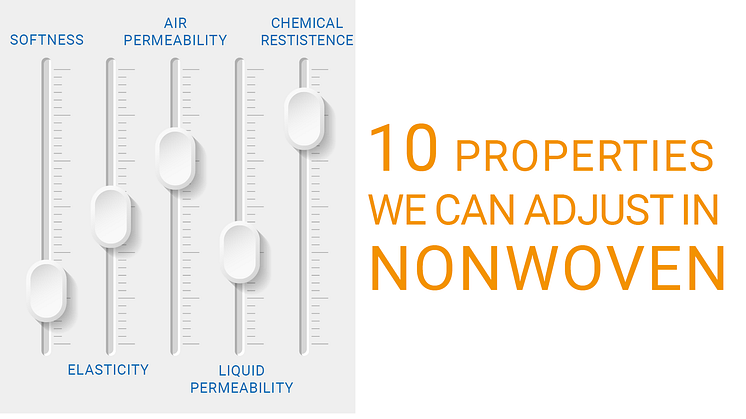

Nonwoven is not ONE material – it’s a family of many different materials. There are at least ten different type of nonwoven materials. Each material can be designed with different properties – making nonwoven such a loved material in manufacturing companies within many industry segments

Exceptional range of properties

The range of properties you can achieve and get with all types of nonwoven materials is truly exceptional. There are nonwovens ranging from softer and pliable to strong and durable. Some materials, such as spunbond, can be both.

Many nonwoven materials are resembling fabric in its texture, but there are also nonwovens that also resemble paper (such as wetlaid) or rigid plastic (such as fiberglass)

Nonwoven has a very dynamic relation to liquids and air. There are nonwovens designed to block water or air – but there are also nonwovens that allow water or air to pass through. There is nonwoven that can absorb water – other doesn’t absorb.

There are nonwoven (such as spunbond or fiberglass) that handles really harsh conditions, such as heat, UV-rays, alcohol and electricity.

How to design properties?

The fiber material used to produce the nonwoven of course has a great affect on the materials end properties. Nonwoven is made from different, often plastic, fibers which in return also can be mixed with other material. Nonwoven can be coated with other materials to add or change properties.

The manufacturing process also has an effect – some materials can be heated (thermobond nonwoven) or treated with chemicals (chemically bonded nonwoven) to make them less airy, harder, softer or more/less sturdy. Some nonwovens are treated or bonded with different needles to create the perfect permeability for liquids or air.

Some are using endless long fibers and other nonwoven are made from chopped shorter fibers which in return creates different properties.

Different nonwoven materials

Read more about each material by following the link – it goes to Scandinavian Nonwoven’s material guide. You can also order sample of different nonwovens there.

- Spunbond: the most flexible nonwoven material

- Coated nonwoven: nonwoven can be coated with other materials to effect permeability and durability

- Chemically bond nonwoven: soft and gentle nonwoven

- Elastic nonwoven: a stretchable nonwoven

- Wetlaid: paper-like nonwoven

- Spunlace: soft and stretchy

- Needle punched felt: soft or sturdy with high or low permeability

- Fiberglass: robust and durable for harsher conditions

- Thermobonded Nonwoven: Absorbing, Elastic and Good for Cleaning

- Sustainable nonwoven: Nonwoven that can be biodegradable, easily recycled or reused.

Industries that use Nonwoven

Different industries use nonwoven very differently. Nonwoven is used in construction, hygiene products, hospitals, food packaging, furniture & beds, cars & boats, absorbents, filtration and wipes.

Follow the links above to learn more about how nonwoven is used in different industries on our website, At the website, you can also order nonwoven samples. or read our article “Get inspired: how other industries use nonwoven”