Pressmeddelande -

Transmission Laser Welding of Plastics Design Guidelines “light”

Introduction

The purpose of this document is to provide designers and engineers, in the concept and design phase of new products, with a brief understanding transmission laser welding of plastics.

Basic Laser Welding Process

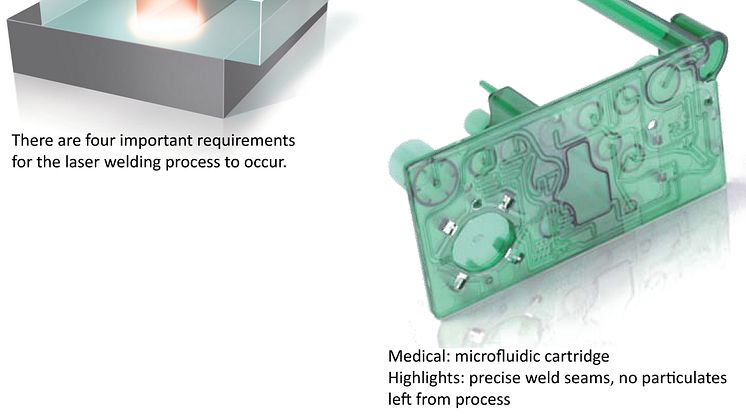

Laser plastic welding is a method of bonding two or more thermoplastic components together. Although there are many methods for joining thermoplastics, laser plastic welding has a few clear advantages: higher joining quality, minimal resulting flash or particulates, higher quality controls, less stress to the component and the ability weld complex and intricate shapes.

When plastics are joined by laser welding, the laser beam passes through the laser-transmissive upper part to transfer its energy to the lower, laser-absorbent part. Moderate clamping pressure ensures reliable heat conduction between the two joining partners. The weld seam plasticizes, and sets after cooling to form a secure, strong weld.

Important Requirements

1. Laser Transparent Top Layer

The

upper joining partner must be sufficiently transparent to the wavelength of the

laser to allow the laser beam to pass through the component. Plastic that is transparent

to laser light is either pure or contains non-absorbent pigments.

Laser-transparent plastics are not necessarily transparent to the human eye. The strength of the energy needed in the laser beam to achieve proper welding at the joining line process is dependent on the transparency of the transmissive plastic in the upper layer. The transparency is dependent on the additives, fillers and the thickness of the material.

2. Laser Absorbing Bottom Layer

The laser absorbent layer is

responsible for turning the remaining laser energy, once passed through the

transmissive layer, into heat at the interface of the two layers.

A commonly used additive to make plastic absorbent for IR laser light is carbon black (typically 0.2-0.4% by volume) since it is very economical. However, there is also a variety of other additives, including colorings, which are IR absorbent.

Note, it is possible to weld two pieces of clear plastic to one another, either using a special additive, (Clearweld™ by the Gentex® company) or by using special laser wavelengths.

3. Material compatibility

The two polymers, which are to be joined, must be of the same

plastic family with similar resin properties to be joined successfully; otherwise one part may melt

or burn and the other will be unaffected.

The following materials are known to have been successfully welded: PA 6, PA 66, POM, PBT, PC, ABS, PP and PE in their pure form. For a more detailed listing of compatible plastics please request a “Materials Compatibility Chart” from a LPKF Laser Welding specialist.

4. Contact

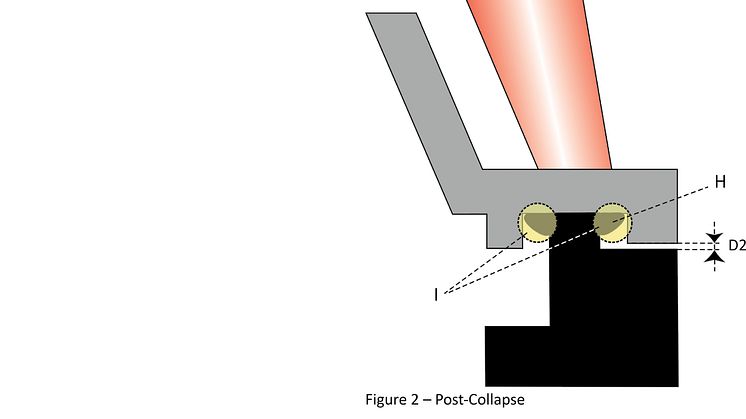

It is paramount that heat energy,

generated on the surface of the lower layer, be transferred to the upper layer

so that it may become molten as well. In order for conduction to occur the two

layers need to be in contact during the welding process.

Contact and pressure are typically accomplished with various methods of clamping devices, see letter “G” from Figure 1 below.

Read more about Transmission Laser Welding of Plastics Design Guidelines

Ämnen

Kategorier

Regioner

Solectro AB grundades 1983 av Gerhard Tetzlaff.

Verksamheten omfattas av utveckling, produktion, försäljning och service av komponenter för automatisering, komplettlösningar, specialmaskiner, robotar, CNC-maskiner,PCB-prototying, laser, SMD samt dentalmaskiner.

Solectro AB är beläget i Lomma - ca. 10 minuter från Malmö och Lund.

Adress:

Tenngatan 6 - 8, 234 35 LOMMA

Tel. 040-536600

Fax 040-536610

E-mail: solectro@solectro.se

www.solectro.se